PASSAGE SUMMARY

For a brief understanding of differences among DTF, UV and UV DTF printing, please refer below chart.

Main Differences among DTF, UV and UV DTF Printing

Printing media

fabric

better flat objects,

cylinder objects (extra jigs needed),

fabric excluded

almost all object surfaces,

fabric excluded

Application

garment decorating industry,

home decors

customized products including phone case, mug, bottles, etc

customized products including phone case, mug, bottles, etc,

suitable for mass producing

Consumable&devices needed

ink,

film,

adhesive powder,

curing machine,

heat press

ink,

optional jigs

ink,

AB film,

laminator

Printing steps

1. print on film

2. spread powder

3. cure powder

4. heat press on fabric

5. peel off

directly print on object surfaces

1. print on film

2. laminate/transfer

3. apply onto substrates

4. peel off

Ink needed

DTF inks

UV inks

OR

UV+varnish inks

UV+varnish inks

Single head

cartridge numbers

6 = CMYKWW

6 = CMYKWW

not available

Dual heads

cartridge numbers

12 = CCMMYK + W*6

12 = CCMMYK + W*6

OR

12 = CCMMYK +V*6

12 = CMYKWW + V*6

Three heads

cartridge numbers

not available

18 = CCMMYK+W*6+V*6

OR

18 = CCMMYK+W*12

18 =

CCMMYK + W*6+V*6

** C=cyan, M=magenta, Y=yellow, K=black, W=white, V=varnish **

** C=cyan, M=magenta, Y=yellow, K=black, W=white, V=varnish **

Main Differences among DTF, UV and UV DTF Printing

fabric

flat hard objects,

cylinder hard objects (jigs needed),

fabric excluded

almost all object surfaces,

fabric excluded

garment decorating industry,

home decors

customized products including phone case, mug, bottles, etc

customized products including phone case, mug, bottles, etc,

suitable for mass producing

ink,

film,

adhesive powder,

curing machine,

heat press

ink,

optional fixtures

ink,

AB film,

laminator

1. print on film

2. spread powder

3. cure powder

4. heat press on fabric

5. peel off

directly print on object surfaces

1. print on film

2. laminate/transfer

3. apply onto subjects

4. peel off

Single head

cartridge numbers

6 = CMYKWW

6 = CMYKWW

not available

not available

18 = CCMMYK+W*6+V*6

OR

18 = CCMMYK+W*12

18 =

CCMMYK + W*6+V*6

** C=cyan, M=magenta, Y=yellow, K=black, W=white, V=varnish **

** C=cyan, M=magenta, Y=yellow, K=black, W=white, V=varnish **

① How do the three printing methods achieve their printings?

Combining the needed consumables and devices, along with the related printing steps, let’s first take a look at how do these three printing methods achieve their printings?

DTF printing- also called Direct to Film printing, it prints graphics on PET film.

How it works:

Printer prints on film - adhesive powder spreading - powder and ink cured by curing oven - printing heat pressed on fabric - film layer peeled off

Through bonding among PET film, DTF inks and adhesive powder, colors will be attached onto fabrics with durable and high quality effect.

UV printing- also called Ultra-Violet printing, it prints directly on object surface. UV printers tend to be configured with a built-in printing platform.

How it works:

Blank object put on the printing platform - object placement and printing position adjusted - printer prints on object - printing cured by built-in UV lamps

It’s obvious that UV printing only requires quite less procedures. However, confirming the printing position sometimes means a lot of adjustment works.

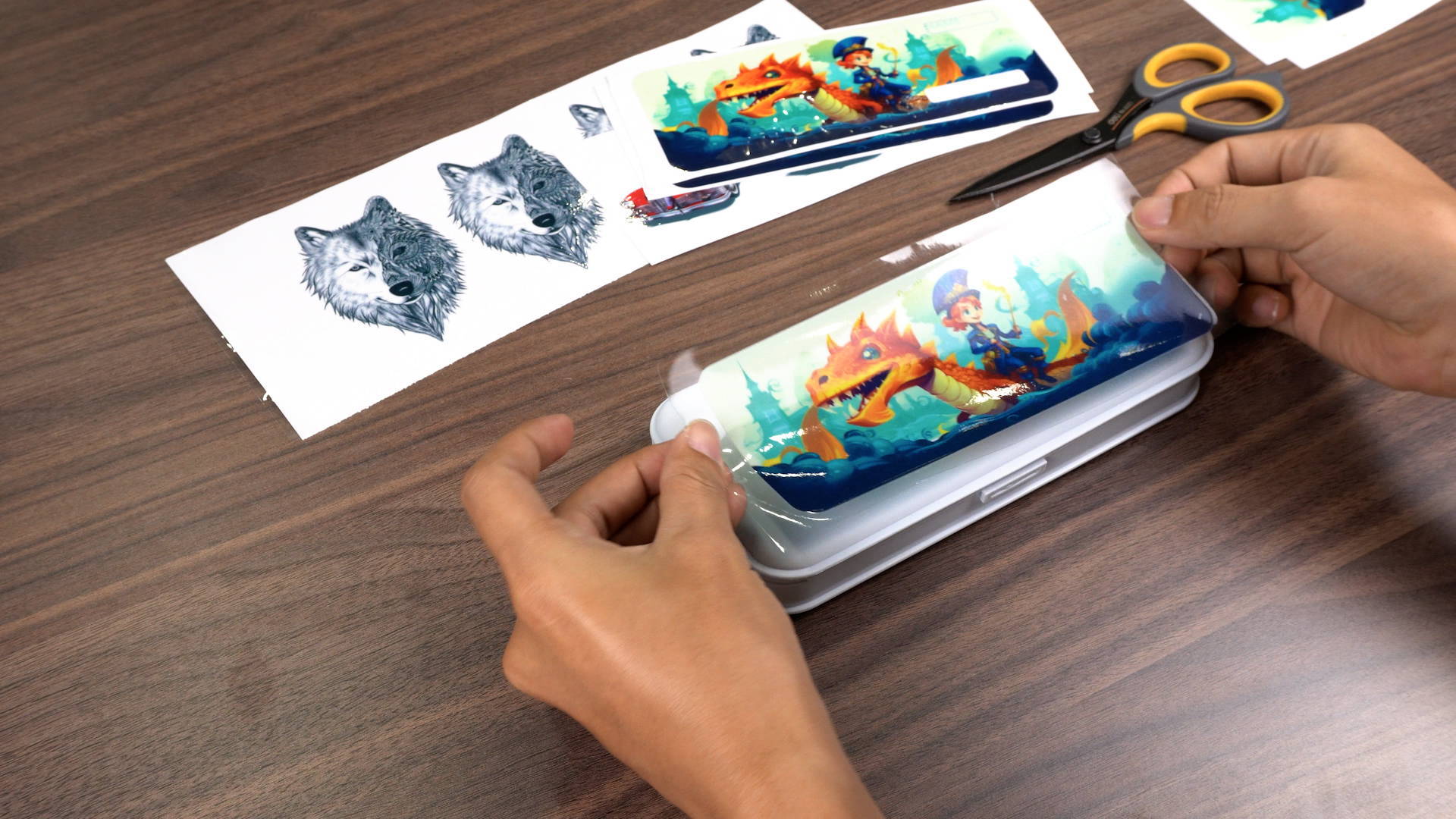

UV DTF printing- as the name implies, it’s kind of a combination of UV and DTF printing, it works perfectly as a crystal sticker maker.

How it works:

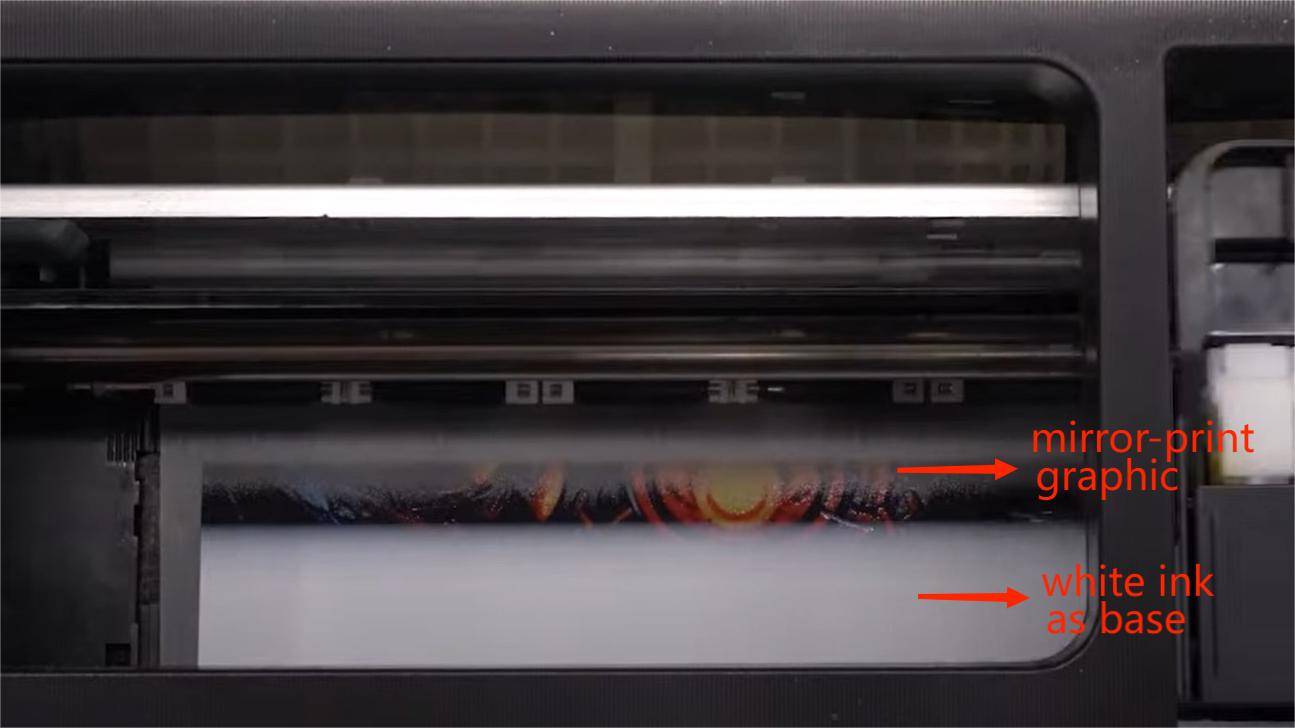

Printer prints on A film/base film (PET film) - printings cured by built-in UV lamps - A film/base film (with glue on it) and B film/backing film laminated - A film/base film peeled off, printings and glue transferred from A film/base film to B film/backing film - printings/stickers attached on blank object - B film peeled off

Laminating and transferring are the two most essential parts in UV DTF printing. Only through these two procedures can printings be endowed with viscosity and transformed into crystal stickers.

② How can the three printing methods be applied?

This part will generalize on what substrates and in what fields can these three printing methods be applied.

DTF printing- Recommend to apply on fabrics only, including wool, nylon, pure cotton, polyester fiber, lycra, linen, denim, silk and so forth materials.

DTF printing is commonly used in garment decorating and customization industries. And as DTF printer becomes more and more prevalent and affordable, some people use it to produce individual home decors like tapestries, coasters and so forth.

UV printing - Can be used on variable materials including wood, metal, crystal, acrylic, glass, leather, lithograph and so forth, BUT not suitable for fabrics.

UV printing is widely used in small businesses like wood printing and phone case customization. It’s highly recommended to apply UV printings on flat objects only. For bevel or cylinder ones, there will be extra jigs needed.

UV DTF printing - It shares similar suitable materials and appliance as UV printing, but with broader possibilities, including:

A wider span of materials - UV DTF printing can directly patch on objects like mug, bottle, things of bevel or cylinder shapes. But still, it’s not suitable for fabrics.

A bigger production quantity - UV printing achieves quite limited printings since the size or quantity of blank objects is somehow limited by the printing platform. UV DTF transfers however, is capable of producing mass quantity of crystal stickers at a time.

③ How does the print head number affects printing?

A print head is a critical component of a printer that controls the actual application of ink onto the print medium (such as paper, fabric, or film). It contains a series of microscopic nozzles through which ink droplets or toner particles are precisely deposited to form the text, images, or patterns desired.

Generally speaking, the number and configuration of print head directly impact the printing speed and quality of a printer, in the ways like:

On the one hand, let's take double print heads for example. Compared with single print head, double print heads are equipped with more nozzles spraying inks at the same time. This parallel processing allows the printer to produce higher redundancy printings in a shorter time.

On the other hand, in some printers, multiple print heads can increase print quality by dividing the workload or dedicating specific heads to different ink types or colors.

Take Procolored printers for example. From the above chart, it’s not hard to find that for printers with multiple print heads, the 6 cartridges of an extra print head always are in charge of a single ink color - white or varnish.

In most printing practices, white ink always acts as the base color of the entire DTF or UV printings, varnish ink instead as the top layer of the entire UV or UV DTF printings. Configured with an extra print head dedicated for such single color will highly improve the related printing speed and accuracy, making bigger format graphics printed in a shorter time possible.

④ What are the pros and cons of the three printing methods?

DTF printing & DTG/sublimation printing - Compared with DTG (Direct to Garment) printing or other sublimation printing, DTF is free from fabric pre-treatment and can be used on a wider scope of fabric colors and substrates.

However, for DTF printing, the bonding between inks and fabric is not close and strong as the one in DTG and sublimation printing, leading to a less breathable fabric output.

UV printing & UV DTF printing- UV printing and UV DTF printing share many things in common: both of them can only be printed on objects but not fabrics; both of them can apply varnish.

However, unlike UV DTF printing, UV printing can not achieve the same excellent printing effect on cylinder/bevel objects as on flat ones; also, the built-in printing platform somehow limits the size and quantity of objects waiting for customization.

UV DTF printing does provide lots of convenience for object customization - the crystal stickers it makes is suitable for applying on most objects, even on objects of irregular shapes; the crystal stickers it makes can be produced in batch, highly improve the production efficiency. However, compared to UV printing, UV DTF printing requires much more operation procedures like laminating, causing a higher printing cost.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!