PASSAGE SUMMARY

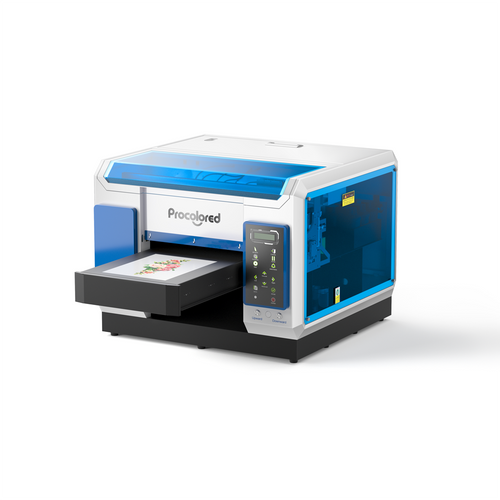

To start our UV DTF journey, let’s first understand how does an UV DTF printer work. Here we present a rather simplified working process of an UV DTF printer. From the diagram above we can clearly see that through automatic printing and laminating, an UV DTF printer is able to produce crystal stickers for instant applying. So how can it make that attainable?

(Above details are only for Procolored UV DTF Mini. For other ordinary UV DTF printers, the laminating function has to be done with an extra laminator.)

1. What’s UV DTF Printer and How Does it Differ?

As the name shows, UV DTF printer can be simply regarded as a combination of DTF printer and UV printer.

Same as DTF printer, an UV DTF printer applies inks that can be printed on film, we call that A film (or base film) in UV DTF printing. One key difference is that the printed inks don’t need further powdering and oven-drying on it, instead these inks are designed to be cured instantly by UV lamps.

Same as UV printer, UV DTF printer applies color inks as well as varnish ink. After printing, all the inks will be exposed to the built-in UV lamps for instant curing, guaranteeing the printing stability before the laminating.

Noticing these two similarities, now let’s take a closer look at Step 2 of the UV DTF Mini working process. Here are the main procedures that usually happen during this process:

Printing - After receiving and translating the printing task from Step 1, UV DTF Mini will start to print on A film (base film, with glue on it).

Curing - At the same time of printing, the built-in UV lamp set above will instantly cure the inks via high heat.

Laminating - Here comes a new character, B film, or we can also call it backing film. The laminating process is in fact a transferring process - A film and B film will be laminated when they both pass the heating bar, and printings and glue will be transferred from A film to B film and be endowed with the ability to firmly stick on object surface. And that’s the moment when a crystal sticker is finally finished.

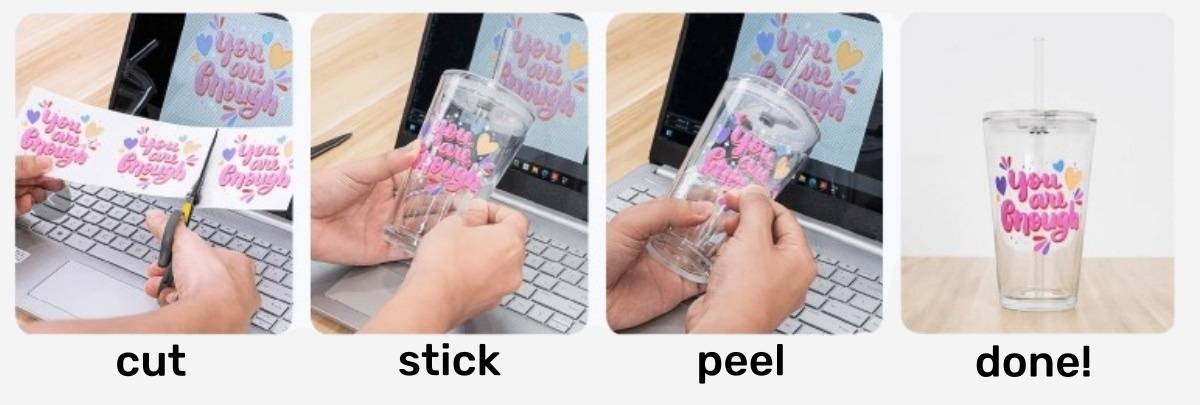

To apply such stickers, we first peel off the A film as Step 4 shows. After applying the printing right on the substrates, we gently press the printings to make the glue fully touch the objects surface, and then we gently peel off the B film.

UV DTF printings can not be applied on fabrics, but still, compared with UV printings, they’ve got a wider span of suitable substrates - they can be directly applied on most curved or flat objects of metal, acrylic, wood, glass, paper, crystal and so forth ordinary or special materials, creating impressive customized mugs, bottles, boxes, cases and so forth objects.

2. A Deep Dive into Procolored UV DTF Mini

With quite the same functions as other UV DTF printers on the current market, what on earth makes Procolored UV DTF Mini stand out?

The truth is that Procolored pays equal attention to both product configuration and customer experiences. We constantly seek ways and methods to improve and streamline the workflows for our customers, and those attempts are successfully achieved via our hot-sale UV DTF product - UV DTF mini:

Printing & Laminating Functions 2-in-1 - For most ordinary UV DTF printers, an extra laminator must be needed to proceed the laminating process. Procolored makes things easier by upgrading this into UV DTF Mini. As it's clarified in 1.What’s UV DTF Printer and How Does it Differ, UV DTF Mini printer combines printing and laminating functions together, effectively streamlining the workflow.

Upgrade with brand new ink circulation system - Siphon white ink circulation system is a Procolored patented ink circulation technology, and it’s first promoted to the DTF printing market through Procolored DTF Pro printer weeks ago. By May, this brand new ink circulation technology will also be configured on Procolored UV DTF mini printer.

Unlike traditional white ink circulation system, siphon system applies siphon effect and diaphragm pump to perform effective ink agitation thus highly improving ink stability and dynamic. With this technology, UV DTF mini, provided by Procolored, will be with less nozzle clogging issues and less working interruptions compared to other printers on the current market.

Wide application & easy operation - UV DTF stickers can be patched on a wide range of materials, despite the object shape.They can be used to make custom products such as mugs, bottles, stationery, boxed and so on. To apply these stickers on your desired object, all you have to do is cutting, sticking and peeling.

Matched printer stand and film rewinder - Given that UV DTF printing needs several types of films running, we’ve configured an extra stand and a rewinder to provide easier simultaneous operation of different films. (Normally the rewinder is for rewinding films with printed patterns). One key is that remember to follow our tutorial videos during the machine setup to avoid any unnecessary incorrect assembly.

Built-in cutter at film exit - During our daily test and showcase, we noticed that using scissors or some other manual ways to cut the printing film can somehow be dangerous and tiresome. To improve that, we added a cutter device at the film exit. By slowly sliding the cutter, users will be able to get their desired printing parts more easily without less possibility of being hurt.

Easy-operated side door - To make the timely checking and maintenance more attainable and convenient, we upgraded the normal side door opening into setting as below - by simply slide the lower button down, the upper small handle will pop out automatically; and by rotating this small handle, the side door can be opened easily without any manual effort needed. This setting will also protect the side door from accidental opening during the transit, hence promising optimal working status of the inner components.

Attentive customer services - As a trusted brand specializing in printing industry for years, Procolored has aroused more than 30,000 new and returned customers. Besides our cutting-edge products, another key reason is that Procolored provides in-time and attentive technical support and customer services.

Despite of inevitable inconvenience caused by global time difference, we form a tech group for every customer in need and provide guides and tutorials via videos, instant online conversations and even on-site repairing (supported by our local branches).

Digital printers can be quite a learning curve for newbies and sometimes even seasoned users. We understand all the helplessness and agitation that may occur due to any printing interruption, so we try our best to be the most trusted back-up and partner for every user.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!