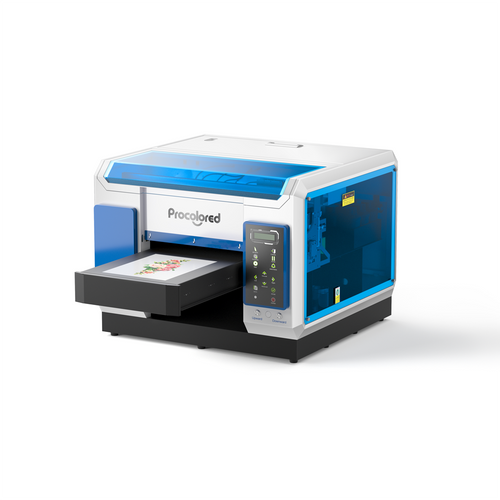

Overview

A conventional UV DTF printer can never bypass the manual laminating process. While Procolored A3 UV DTF printer incorporates the laminator which autocompletes the laminating process. With this function, you can say goodbye to manual lamination and focus more on printing. Compared to the previous generation UV DTF printer, we’ve upgraded the print width by about 30mm, now you can print more patterns on the same film. And the combination of dual printheads and auto-laminating functions will eventually bring the production efficiency to a higher level. A3 UV DTF laminating printer applies patented technology white ink automatic circulation and automatic cleaning to prevent nozzles from clogging. UV varnishing function is another highlight of our A3 UV DTF printer compared to a common DTF printer. Under the action of UV varnishing technology, the printed pattern will be coated with a reflective outer layer that looks more luxurious and more special.

The Procolored A3 UV DTF printer is the ideal choice for customers who want to output high-end patterns and print on uneven, hard surfaces and surfaces with a drop certain degree. Our A3 UV DTF printer overcomes the problem that a UV printer is not able to solve. UV printers have pushed the limits of traditional printers by printing directly on the substrate surfaces of almost all materials. However, printing with a UV printer on the surfaces with a 2-10mm drop(depending on the size and performance of a UV printer) may result in distortion printing. To address this problem, the Procolored A3 UV DTF printer combines UV printing and DTF printing technologies to meet the changing needs of the market. A3 UV DTF printer prints on the film first and then transfer the patterns to the substrate. With this clever idea, printing on all kinds of surfaces with a Procolored A3 UV DTF printer is now possible.

UV DTF Printer and Laminator in One Machine

A UV DTF printer usually takes up significant space, if you need to complete the UV DTF printing process, it’s necessary to place a laminator in your workshop, which will occupy even more space. Given this customer pain point, our innovative R&D engineers came up with a brilliant idea: why not integrate the laminator into the UV DTF printer? And finally, the Procolored A3 UV DTF laminating printer was launched and realizes the goal of completing printing and laminating at the same time. With this advanced technology, printing efficiency is increased by about 25%. Additionally, our new A3 UV DTF laminating printer applies a roll feeder to skip the process of adding films manually and further improve production efficiency.

Dual Printheads Array

Increasing the number of printheads is not just to improve work efficiency, but also to enhance printing accuracy and color vibrancy. A printhead contains a number of nozzles, and the number of nozzles determines the printing speed and quality. With dual printheads installed in the Procolored A3 UV DTF printer, the printing speed will be much faster than single head UV DTF printers under the same conditions.

UV Varnishing & Hot Stamping

Generally, the printer will first print out the special glue first to ensure the film can be laminated successfully, next the white ink and color ink are printed sequentially. The varnish is printed at the last step, which endows the outer layer of the pattern with a reflective look. Patterns printed with varnish will glow at certain angles which differentiate UV varnish printing from ordinary UV printing.

Hot stamping is another eye-catching printing technology that our printer applies. Hot stamping can create golden gloss patterns with a sophisticated and luxury look that can capture people's hearts.

These technologies not only upgrades the visual feeling of the printed patterns, but also endows them with a special sense of touch.

Automatic Cleaning & White Ink Automatic Circulation

For the nozzles clogging problem that affects the printing experience, we’ve figured out our own solution after years of exploration in the digital printing field. The Procolored A3 UV DTF laminating printer is equipped with a cleaning unit that works automatically according to the set interval to ensure the printheads are in good working condition. Our patented technology -- white ink automatic circulation--offers a pump and ink circuit solution to make sure the white ink is in continuous circulation. This white ink circulation method is more scientific than the traditional method which can not provide a circuit for white ink. The combination of these two technologies minimizes printhead clogging and offers a 50% longer service life for printheads.

Why Procolored UV DTF Printers?

Printing with the Procolored A3 UV DTF printer saves you more time and money by integrating with a laminator and utilizing dual printheads array. The UV varnish printing function creates an attractive and fascinating pattern with a glossy look and vivid tactile impression. With the help of our self-developed technologies, printhead clogging can be minimized to prolong the printhead's lifetime and improve the printing experience.

Procolored has explored the digital printer field for more than 15 years and served over 8000 clients from all over the world. It is the powerful R&D capabilities and more than 30 professional engineers that support us on the journey to excellence.