Unlike DTF printing, UV printing achieves prints on rigid objects by depositing inks directly on object surfaces, significantly simplifying the printing workflow and providing print creations beyond garment ornaments.

In this blog, we will take a closer look into UV printing and explore its huge potential in customization business.

PASSAGE SUMMARY

1. What is UV Printing

2. How Does UV Printing Work

2.1 The process of UV printing

2.2 What makes UV printing stand out

3. Understanding UV inks and coatings

4. UV Printings in Actual Practice

1. What is UV Printing

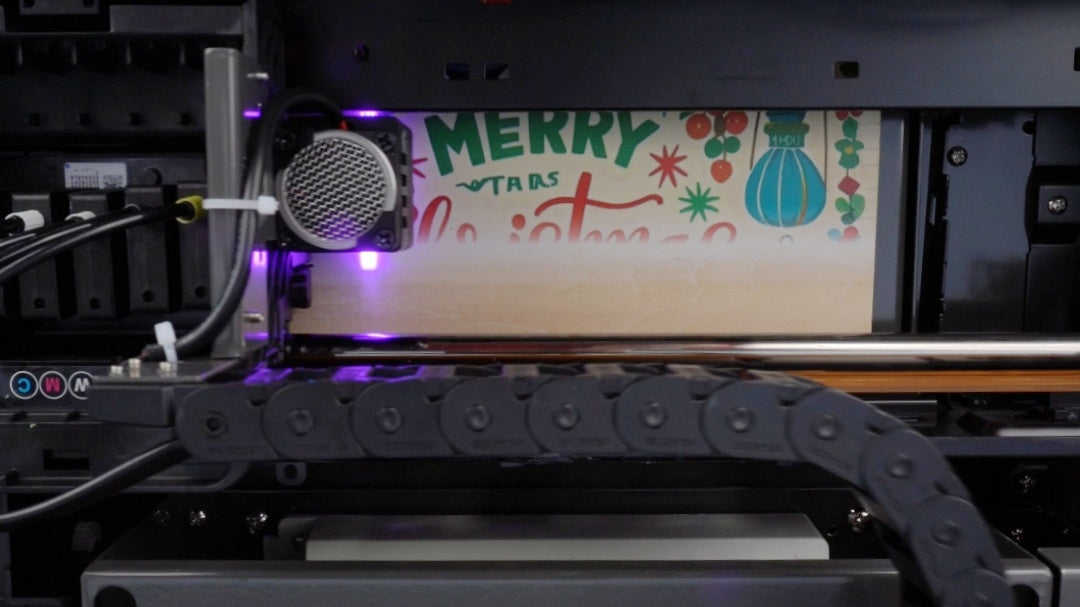

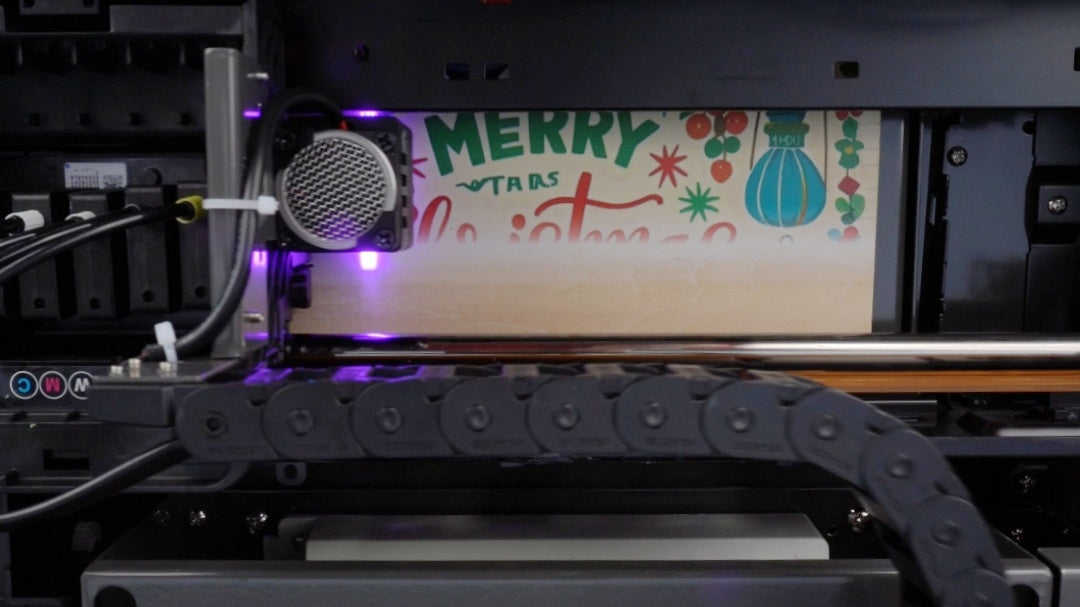

As one kind of popular printing method, UV (Ultra-Violet) printing is frequently applied on leather, wood, acrylic, glass, metal and so forth materials. Unlike heat transfer printings, UV printing deposits inks directly on the desired objects, and at the same time dry them via the built-in UV lights in an UV printer.

2. How Does UV Printing Work

Given the short definition above, an UV printing process might sound concise, easy and simple. Yet it in fact includes intricate, accurate and advanced settings and techniques, as we’re about to discuss in the following passage.

2.1 The process of UV printing

Confirm the printing substrate: UV printing can be applied on a wide range of materials, including leather, plastic, metal, glass, wood, ceramics, paper, leather, etc.

Confirm the object surface: UV printing achieves optimal results on flat surfaces due to the planar configuration of both the printhead and the printing platform. Generally it’s not recommended to apply UV printing on bevel or curved objects, to avoid uneven ink colors or incomplete graphics. But for cylindrical, spherical, pen-like objects, or phone cases, UV printing can also be perfectly achieved with the help of extra fixtures.

Confirm the object height: UV printing is performed by an UV printer, of which there’s a print height limit due to the printer structure and configuration. Before making the final purchase decision of an UV printer, it’s essential to confirm the acceptable print height of your future products. Normally, a wider height range also means a bigger printer dimension.

Confirm the pattern: Confirm your graphic and upload it to the printing software.

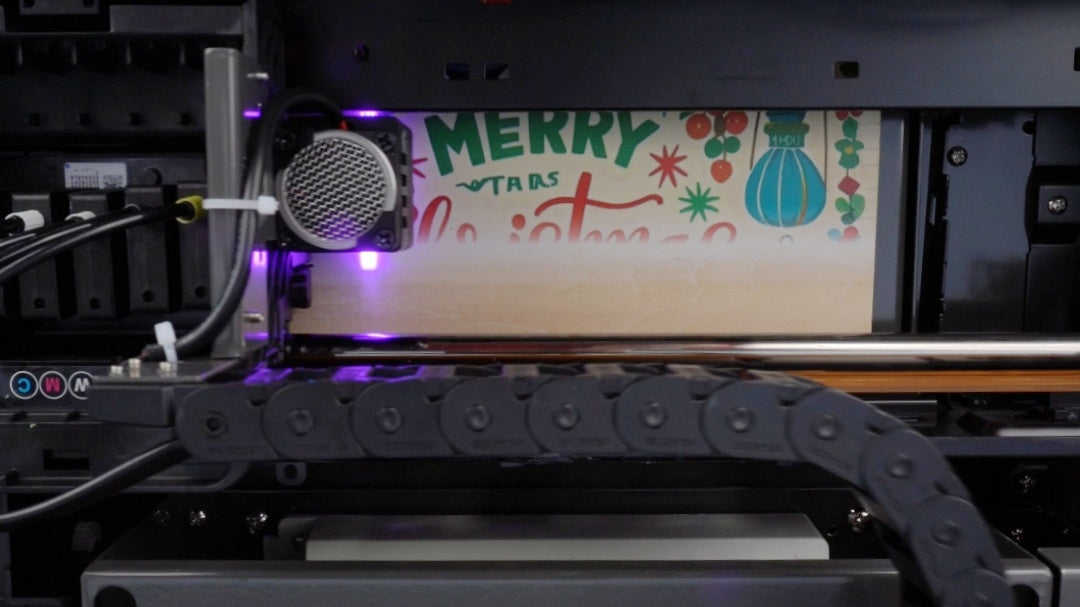

Print & Cure: As it’s previously mentioned, when a printing task is activated, the UV printer will directly print onto the desired object. Simultaneously, the UV lights set at the side of printhead assembly will react with the inks and dry them quickly right after they’re printed out.

2.2 What makes UV printing stand out

For object printing that differs greatly from heat transfer printing, the global printing community collectively calls it DTO (Direct-to-Objects) printing. Besides UV printing, pad printing and screen printing are also the other two major methods of DTO printing.

However, as an emerging digital printing method, UV printing has got increasing attention over the last decades, given its significant advantages as below:

Higher color reproduction: In most scenarios, UV printing winds up with 3 layers of inks - white ink at the bottom, color inks in the middle, and varnish ink on top.

1) White ink: Compared to color inks, white ink as the base layer reflects more light back to the middle layer, providing the highest color contrast and presenting intricate graphic details.

2) Color inks: Unlike pad printing or screen printing, UV printing deposits diverse color inks of different graphic part at the same time, presenting accurate and quick color reproduction.

3) Varnish ink: Varnish ink on top effectively modifies the print with a more glossy finish that highly enhances the visual appeal and vibrancy of colors.

Wider graphic option: First let’s understand how does a specific graphic get printed on objects in pad and screen printing - both of them need a graphic template to create the graphic shape (the ink cup for pad printing and the stencil for screen printing), and it’s obvious that the more intricate a graphic is, the more limits a graphic template would exhibit.

UV printing as a digital printing, on the contrary, exhibits high flexibility in depicting a graphic, name it simple or complex, in solid colors or multi-colors. By depositing the needed inks at the same time and in the accurate position, UV printing offers a wider options for both graphic patterns and colors.

More simplified operation: Now, let’s recall a screen printing process - create a stencil, prepare inks, squeegee the inks onto the desired object, leave the print dry or heat dry it. Pad printing is not that easy also, you have to create an etched graphic first, then the object gets print from the silicone ink cup, then a long time before the print gets dried. UV printing instead, set you free from all these endless effort! All you have to do is put the appropriate object onto the printing platform, then an UV printer will handle them all - detect the print height, execute and instantly dry the printing, then voila, here comes the complete, accurate and durable DTO print!

3. Understanding UV inks and coatings

UV printing works on a wide range of materials, including leather, wood, acrylic, glass or metal, etc. However, due to properties of different substrates, UV inks might present different qualities on diverse materials, and applying specific inks or coatings as below can effectively improve its consistency.

Soft ink: Generally soft ink is provided along with an UV printer by default. Compared to hard ink, soft ink can be universally used on both soft and rigid surfaces, causing less cracking issues.

Hard ink: For people chasing for top-notch printings on rigid items like wood, metal, glass, hard plastic, etc, it’s more recommended to achieve UV printing with hard UV inks. Different from soft ink, hard UV ink exhibits bigger particle dimension and stronger viscosity, delivering printings that tend to be more durable and three-dimensional. Friendly reminder, better not apply hard ink to print on soft materials like leather, rubber, PVC and so forth, or the prints may get cracked easily.

Coating: Here’s another takeaway for UV printings on metal, acrylic and glass - UV printing presents better quality on a less lubricious surface. For extra smooth surfaces, it’s recommended to apply specific coating first, to empower them with appropriate friction and heighten their bonding with UV inks.

4. UV Printings in Actual Practice

The customization of Stanley tumbler has again incurred an increasing global attention on custom objects, and UV printing is one of the preferred printing methods to achieve them. With its simple application, fast drying and accurate printing position, UV printing has undoubtedly unleashed the experience of DTO (Direct-to-Objects) printing.

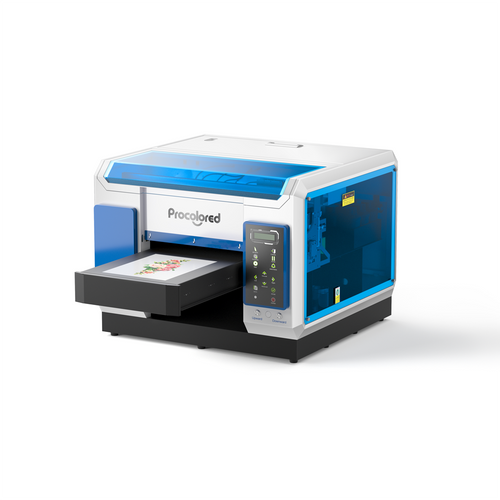

Procolored has further elevated UV printing to a higher standard with its advanced configuration and innovations of the UV printers. Take the product V6 and V10 UV printer for example, besides the top-notch printing quality, these two gadgets are also equipped with impressive features like adjustable printing height, built-in air filter and cooling system, as well as auto-cleaning function of the printhead.

Check out the Procolored UV Printer Review!

- Wilma K.

“ Not a tech savvy here, and the tech team patiently offered

quite attentive help during the setting and printing process!

It's really appreciated and impressive from my side.

Now with all set up I am ready to practise more printings, let the magic happen! ”

- Arthur D.

“ I am really happy with my Procolored UV printer.

Yes yes, some issues at first but the tech support worked everything out.

Did my first UV printing on wood and it turned out surprisingly charming! ”

- Gely M.

“ Got my UV printer together with really helpful guding videos!

Quite impressive support team too, informative and super friendly.

I have a small business, and my custormers are now crazily loving these new items. ”

Most Popular Blogs

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Most Popular Blogs

News and deals, directly to your inbox

Your cart is currently empty.

Start Shopping$643

$482