PREFACE

The printing industry has experienced rapid growth in recent times, with more and more organizations moving to DTF Printers. DTF printing meaning Direct to Film, Printer DTF allows you to obtain simplicity, convenience, consistency in performance with a wide range of colors. In addition, DTF Printers are now a reliable and cost-effective machine to own. So, let us get into the meat of it and find out what Direct to Film Printer can do for you.

Direct to Film or DTF printing is a process that transfers prints onto fabric or other substrates using a heat-press mechanism. fabric or other substrates using a heat-press mechanism. Unlike the DTG method, which only works on cotton fabrics, Unlike the DTG method, which only works on cotton fabrics, the Printer DTF method can work on cotton and poly blends.

As the name suggests, a direct-to-film printer allows you to print a design ona film and transfer it directly to the intended surface, such as fabric. The keyreason why the printer DTF is gaining prominence is the freedom it gives youto choose almost any surface for printing?

The DTF printer technology can allow you to print easily on cotton, polyest

ter,synthetic,or silk without any trouble.Plus, DTF printers can work on both darkand white fabric without any need to press on expensive A & B paper.

First, printer DTF implementation in your printing business does not require a heavy investment.Whether you are new to the printing business or wish to adapt your DTFprinting to expand yourbusiness, taking a closer look at these printers is worth your time.

DTF Modified printers typically come with multiple colored ink t&nks. These tanks aflow theprinters the convenience to operate using CMYK settings. The DTF printer ink isspecifically,designed for use with this process.

Additionally, the DTF process eliminated the use of rollers that previously caused the page toslide.This rectifies the appearance of any linings on your white layer prints. So, if you are.looking for a printing technology with flawless final designs that are an exact depiction of theimage you wanted on the fabric,DTF printing meaning is the choice.

Hot-Melt Adhesive Powder

The Direct to Film printingpowder is a white granularproduct and works as anadhesive material.This helpsbind the colored pigments inyour printer to the surface youare printing on. However, thereare several grades of this STFhot-melt specified in microns.

The Direct to Film Printer Films

A DTF printer uses PET films asthese are different from the onesused in screen printing. Thesefilms are also known as DTFTransfer Films in the market.You can find them as cut sheetsfor small-scale use or as rolls forbig commercial setups.There aretwo classifications of PET Filmsbased on temperature.These are cold-peel type films ana nor-ptype films.

DTF Printer Inks

The inks used in Printer DTF are unique pigments designed in Cyan, Yellow, Magenta,White and Black colors.The white ink forms the foundation of your print, while thecolored pigment prints the design on the film.

Curing Oven

This is a small industrialoven to melt the printer'shot melt powder, whichthen goes on the transferfilm.Alternatively, you canalso use a heat pressmachine to carry out thisfunction.However, it wouldhelp if you used the heatpress machine in a no-contact mode.

Heat Press Machine

This piece of equipment helpstransfer the printed images onyour film onto the desiredsurface or fabric.You can alsouse this machine to melt

powder on your DTF film.

Software for DTF Printer

Software is an intogral part of DTF printers.This is because softwareinfluences the color performance, print characteristics of the inks, andfinal print performance.For DTF printing, you will require specializedRIP software to handle your white and CMYK colors.

lt is essential because software governs the colorptofiling drop sizas,ink levels, and several critical factors contributioe to printt quility.

Automatic Powder Shaker

This Direct to Film printer component is more common for commercial use(where DTF printer applies the powder) in an even fashion. Plus, the powdershaker also removes excess powder.

So is if worth investing in a Direct-to-Film Printer?

First , let us look at the merits and demerits of this exceptional piece of technological advancement in the printing industy.

PROS

lt does not require any pretreatment

You can use it on almost any material or fabricThe material it is printed upon will still have a slighthand feel to it when you touch.After the printing, thfabric will exhibit excellent wash resistance.

The process is less tedious and quicker than otherprinting methods such as DTG.

CONS

The printed area is slightly more noticeablethan subliminal printing

The color vibrancy is somewhat lower thansublimation printing

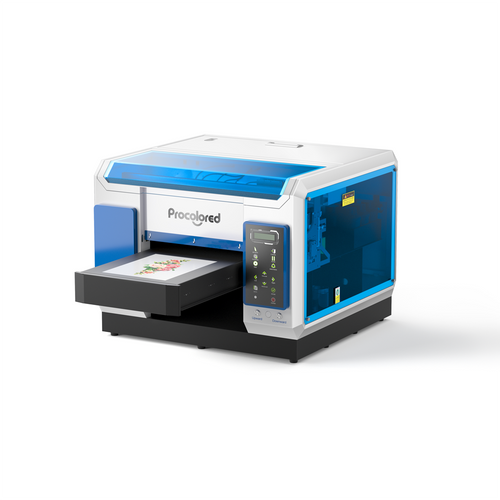

Procolored printer,outstanding in the small inkjet printers for more than 15 years.To print on almost anything this printer brings unlimited possibilities for your business.

The company mainly engaged in Inkjet printer/ flatbed printer / digital printer. Having a very good reputation because of stable productperformance, good printing effect,unique appearance and sincere servic. The factory orea is 1800 square meters, hos provided a full rangeof sevices for customers or agents from all over the world, and has obftained a number of patents.

There are more than 20 engineers to ensurethe quality of production and after-soles service.We always adhere to the concept of high quality and full ronge of services,including OEM/ODM, fast delvery from overseas warehouses, 3 year quality warranty, overseas e-commerce platforms one-stop service and so on.Commtted to offer the best tech support, after-service and reasonable price to build the long term business cooperation with our customers.