Dos and Don’ts

of Inkjet Printers

Wondering if you are treating your printer right?

Below tips might offer you some new thoughts!

Keep waiting for more tips to be continued!

PASSAGE SUMMARY

set up the machine in a hurry without following instructions, and wonder why it doesn’t work

plug the USB flash drive into your computer, check all the tutorial videos before setting up your printer

TIP 1 : Yes we have tutorial videos

Along with the printer, Procolored also attaches an USB flash drive, a RIP dongle and an USB-3 adapter. These three devices are provided to function as below:

The USB flash drive contains tutorial videos concerning product unboxing, printer/software setting up, printing operations and machine maintenance. Taking some time to watch all these will do you a great favor in getting used to your new machine friend.

The RIP dongle is a key needed every time you open RIP software on your computer. Friendly reminder, RIP software is compatible with Windows system only, better get a back-up computer if you’re using Macbook.

The USB-3 adapter is a gigabit LAN adapter. It’s used to connect computer and printer together to allows higher data transfer speed.

We also highly recommend laptop users to get a USB splitter or a USB hub, so that all the mentioned USB-port-needed devices can be applied at the same time to provide more detailed setting up instructions.

violently pull the ink damper out, hold it upside down, or hardly press it

always treat the ink damper gently and carefully

TIP 2 : Treat ink damper with tender

Ink damper, or ink cartridge, is a replaceable component of an inkjet printer that contains the ink used to print text and images on paper. Generally it is located in the print head assembly and has a vent hole on it.

Pulling the ink damper out with violence, pressing it hardly or holding it upside down might damage it and cause ink clogs or ink leaks, hence leading to poorer qualities of printings.

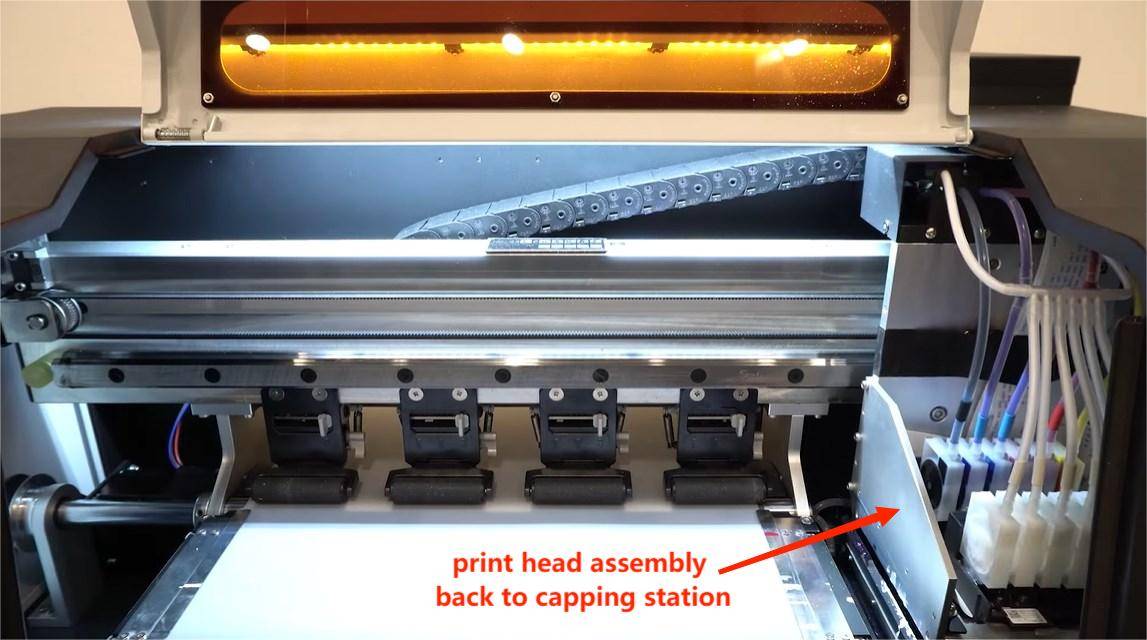

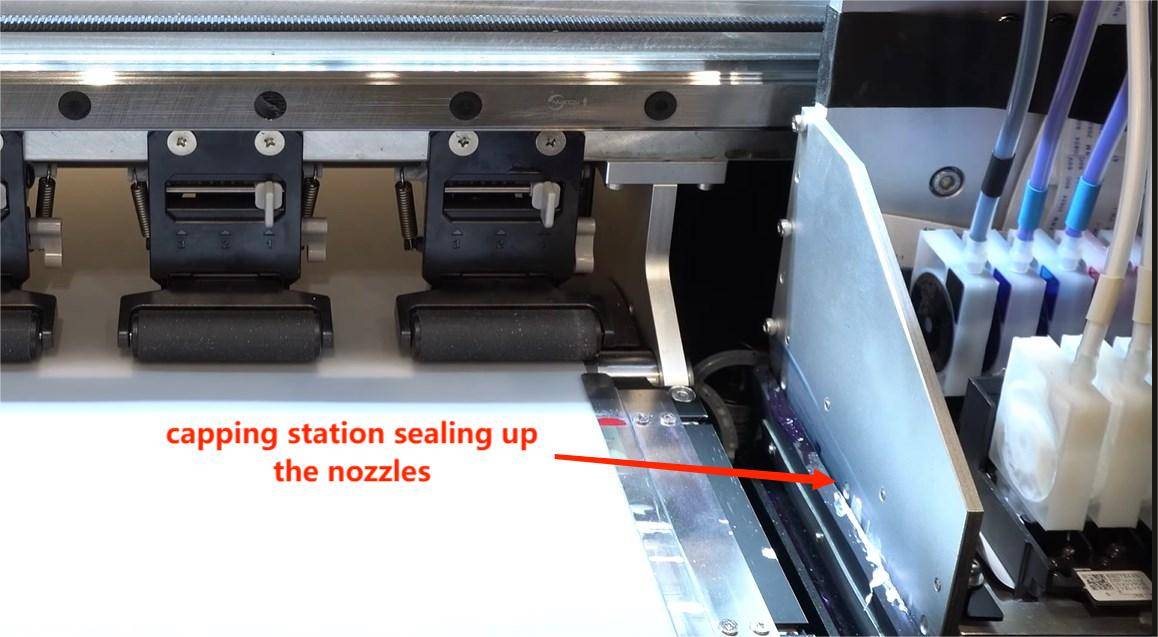

have developed a good habit of regular printer cleaning but left the print head assembly far away from capping station every time

make sure the print head assembly is on the capping station side when the printer is idle

TIP 3: Always keep the print head assembly on the capping station side

Capping station functions in the ways as below:

keep the nozzle moisturized when the printer is not in use

help to apply cleaning fluid to wash away ink residues during the cleaning process

regulate the air pressure within print head to promise high printing quality

Normally after every printing or self-cleaning task, the printer will automatically move the print head assembly to the capping station side. But it’s possible that we might move it to other side when we need to extract ink from ink cartridge, or when we are busy in cleaning the guide rail.

While the printer is not in use, a good habit of checking the print head assembly's position from time to time will save you from potential troubles.

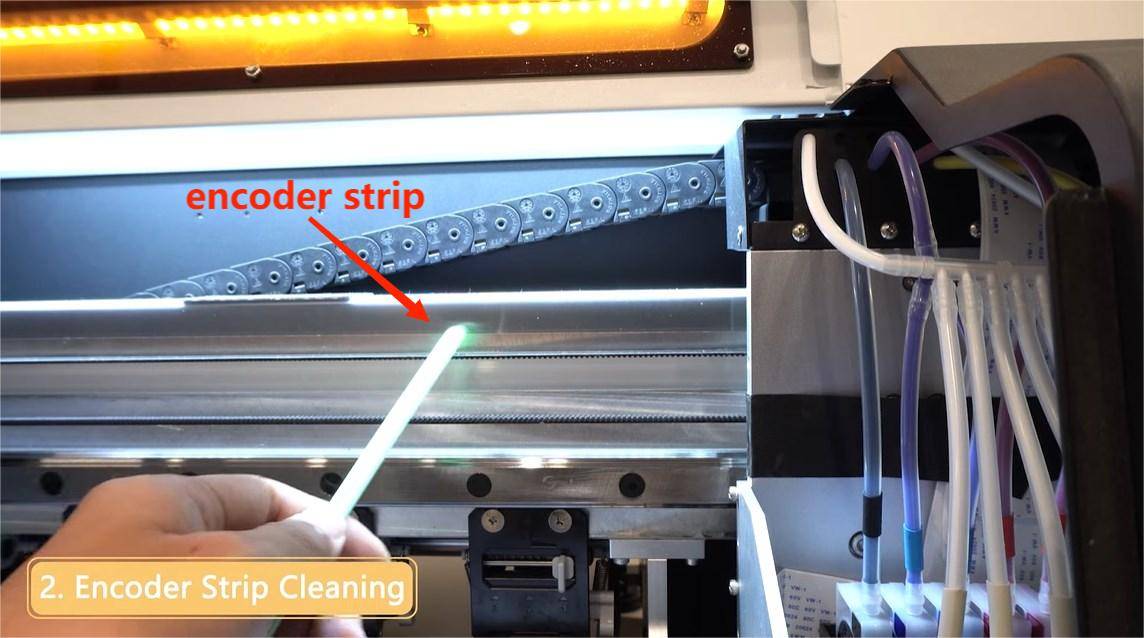

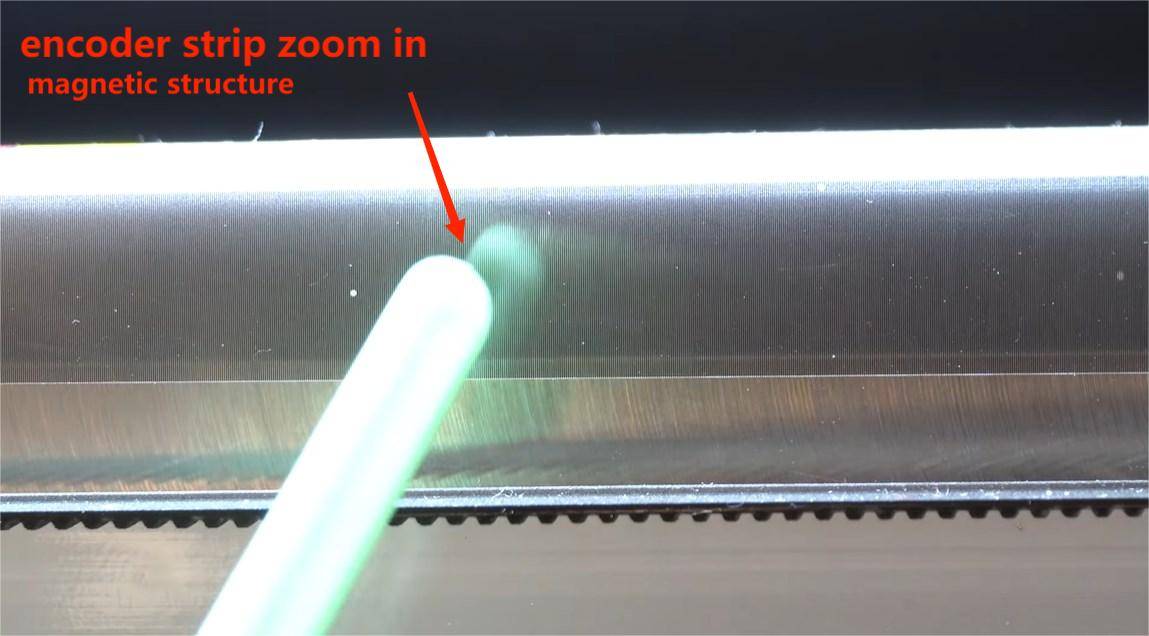

hold the encoder strip in hand and use a tissue paper to clean it

try not to touch the encoder strip with your fingers and use a lint-free cloth to clean the printer instead

TIP 4 : Leave your printer clean and dust-free

Encoder strip is a sensitive component with lots of magnetic strips on it. It translates the printing task and help confirm the printing position by sending orders to the print head.

Fingerprints, lint or fibers on tissue paper, such things left on encoder strip will damage its sensitiveness and thus leading to inaccurate printings. And they will do the same harm to printing platform or any other inner components of a printer too.

When cleaning inner parts of a printer, we highly recommend to use soft, lint-free cloth or swabs instead. Also, better move or clean those components in gentle and slow movements, this will help maintain the high performance of printer.

use alcohol to finish cleaning for the entire printer

follow Procolored video and avoid applying alcohol on some specific areas

TIP 5 : Some printer components are alcohol-intolerant

Alcohol is recommended for printer cleaning as it owns higher cleaning efficiency and lower damage possibility , except when being used for capping station or print head bottom.

These two areas are places either contain or directly touch the printing nozzles. When a nozzle (which includes super tiny holes) meets alcohol (which evaporates much quicker than water) , the ink on the nozzle surface might get dried faster and cause clogging issue.

Instead, for these two areas we suggest to apply moisturizing cleanser. Remember the purpose of machine cleaning is to alleviate any potential problems but not create new problems. Pay the most attention to protect the nozzles during cleaning process will always do you good.

Check Procolored videos related to maintenance to get more detailed information.

found the white ink not thick enough on printing, so keep adding white ink in the ink tank

ink lacking may be and may not be the reason of thin white ink, better follow maintenance suggestions or contact customer service to figure out the exact problem

TIP 6 : Don’t be afraid of white ink, it’s not knotty

White ink works as the base layer of other colors in most printings. Without a sufficiently thick white ink base, a printing might get dimmer or less saturated. It’s totally reasonable to get hurry-scurry when facing thin white ink issue, yet directly adding white ink without taking other possibilities into consideration may result in more severe situations.

Normally thin white ink might be caused by below reasons:

insufficient or expired white ink

sediments in white ink bottle

nozzle clogging

stuffed up filter in white ink damper

low ratio setting of white ink in printing software

Getting to know more about white ink and related cases from other people, will be helpful in quicker troubleshooting.

put the printer on the shelf and happily leave home for a new-year-holiday

take the printer moisturizing maintenance as a regular ritual before a long-time-no-use

TIP 7 : Protect the print head from drying up even it’s not in use

We usually encourage users to use the printer as much as possible to maintain its productivity. But of course we understand there are moments when we don’t need a printer, say during being out for a long vacation.

Here’s the tip: no matter you’re heading out for your vacation, or just staying at home without any printing plans, as long as the printer will be idle for at least 3 days, we recommend you to follow our video and do printer moisturizing maintenance.

Moisturizing maintenance is a process of replacing original ink cartridges and ink tubes with new ones full of moisturizing fluid. This fluid will help avoid potential drying up or clogging issues.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!