Meet UV DTF inside and out

We’ve discussed UV DTF printing a little bit in the previous blog A deep dive into Procolored UV DTF Mini. And we notice that it might not be enough and exhaustive to most new beginners. So here we are!

Scroll down to get more information about UV DTF printing!

PASSAGE SUMMARY

1. On what materials can UV DTF printing be applied?

A very first must-know of UV DTF printing is that unlike DTF or DTG printing, it can not be used on fabrics - this is limited by the UV inks it uses. Take DTF printing as a comparison reference, to summarized their main differences, we can describe DTF inks as “heat activated” and UV inks as “UV-light activated”.

DTF inks are designed with specific chemicals compatible with PET film and fabrics. Together with adhesive powder, through curing and heat press, the DTF inks can achieve really close and firm bonding with fabrics.

On the contrary, among all the chemical elements in UV inks, there’s one kind called photo-initiator. Photo-initiator can be cured by UV lights but not involving any absorption and integration process. Once the UV inks are cured, they will become a solid layer sitting on top of the substrate rather than integrating into it.

Hence, UV DTF printing are more commonly applied on rigid materials including wood, metal, glass, acrylic and so forth. And the harder the material surface is, the stronger viscosity it will present.

2. Sounds like UV printing? What are the differences?

UV inks, UV lights, rigid materials - sounds like UV printing?

Yes, both of UV and UV DTF printing use UV inks and UV lights, and they can be applied on similar materials.

But no, when we dive deep into the printing process, there are huge differences between the two.

Printing method - UV printing directly prints on objects, while UV DTF printing produces and can only produce stickers to apply on objects.

Printing height - Normally, UV printers are designed with an adjustable printing platform, allowing to place about-to-print objects thin as paper and thick as those measuring within 14cms in height or depth. However, the printing height of UV DTF printer is just about 2~3 mm, only allowing the making of stickers.

Object shape - UV printing has higher requirements of the desired objects: they better be with flat surfaces but not with bevel or cylinder ones, better be within the maximized printing height, etc. Instead, since UV DTF printing is applied on objects finally as a crystal sticker, it is suitable for most rigid regular or irregular object surfaces.

Application of varnish ink - Varnish ink is optional for UV printing, but it’s definitely needed for every UV DTF printing. This will be discussed in the following passage, please refer to 4.Is varnish a must-need for UV DTF printing?

3. How does UV DTF printing work?

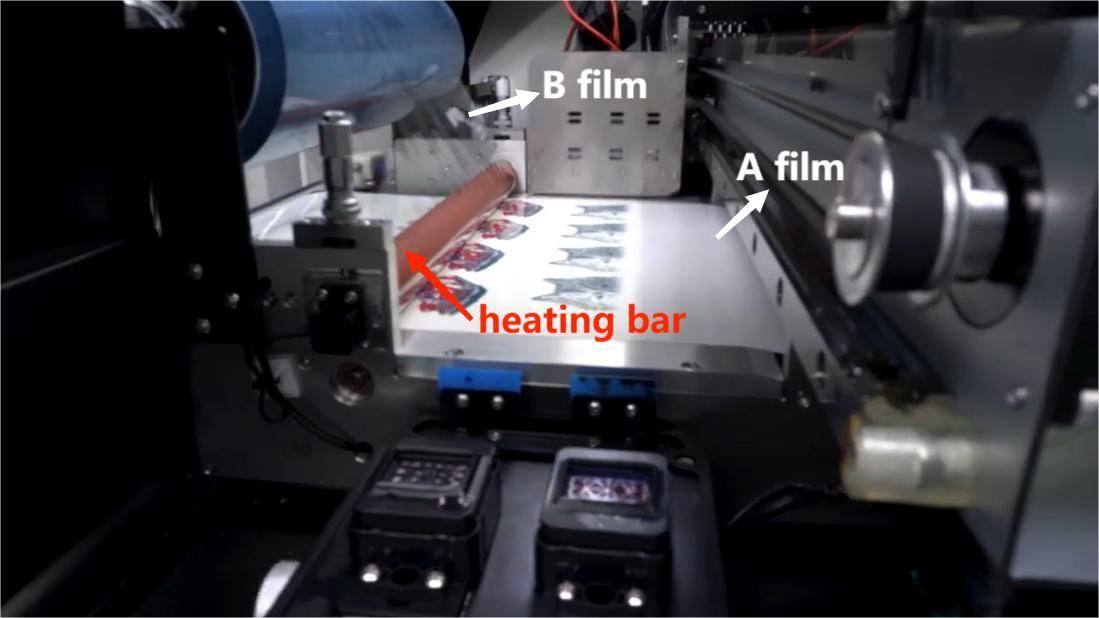

The main process of UV DTF printing can be summarized as above and it involves two special consumables : A film (or base film) and B film ( or backing film). The magic mainly happens during the Step 2 so here we take it out to get a closer look.

Three functions are ongoing actually during the step 2 process:

Printing - After receiving and translating the printing task from Step 1, UV DTF printer will start to print on A film.

Curing - At the same time of printing, the built-in UV lamp set above will instantly cure the inks via high heat.

Laminating - The laminating process is in fact a transferring process - A film and B film will be laminated when they both pass the heating bar, and at the same time the printings and glue will be transferred from A film to B film and be endowed with the ability to firmly stick on object surface. And that’s the moment when a crystal sticker is finally finished.

(Above details are only for Procolored UV DTF Mini. For other ordinary UV DTF printers, the laminating function has to be done with an extra laminator.)

4. Is varnish a must-need for UV DTF printing?

It's feasible to do UV DTF printing with or without varnish ink. But sincerely we highly recommend to proceed UV DTF printing with both UV and varnish inks, as varnish ink in fact functions as below:

Enhancing color presentation - Printings may appear less vibrant and striking without the soothing and finishing effect of the varnish layer. Varnish ink endows every printing with glossy effect that highlights both colors and shapes of printing.

Providing protective layer - The protection lies in three parts : 1) Varnish ink effectively prevents any potential color bleeding and less defined edges of the printed UV inks, providing a more intact and complete color presentation 2) Varnish ink endows UV DTF printing with stronger adhesion and viscosity, allowing it to be transferred more easily 3) Time flies, sunlight travels, and climate changes, inevitably UV DTF printing will one day fade. But with varnish ink on top of it, it will be more sheltered from potential scratching and water damage, capable of higher durability.

5. Is laminating a must-need for UV DTF printing?

We've discussed the laminating process in 3.How does UV DTF printing work? And yes, it's a must-need for UV DTF printing, because it’s designed to be and because without it, an UV DTF printer can only provide you with nothing but a semi-finished A film of no use.

Why A film will be useless without laminating? Assume we’ve got A film with printing as below, so we actually got printing on top of a glue side that’s to say printing without viscosity; and we got a graphic which will, do remember, be mirrored when we patch it as a sticker. Useless, right?

So yes UV DTF printing definitely needs laminating, to endow printing with durable adhesion and transform it into correct direction.

6. How long can UV DTF printing last?

Normally, UV DTF printing can last 2~5 years, if it’s printed with high-quality inks, pasted on suitable objects and treated with proper care.

The first 24 hours after the UV DTF printing/sticker’s applying is the crucial process during which the adhesion will gradually strengthen and increase. It’s highly suggested to avoid water, alcohol or high temperature during this period.

After the 24 hours, the sticker would stay firmly on the applied objects and be water and scratching resistant. But for tableware patched with such stickers, like cups or bowls, better not put them into microwave in case of any potential damage.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!