Things You Need to Know

Before Buying a Procolored DTF Printer

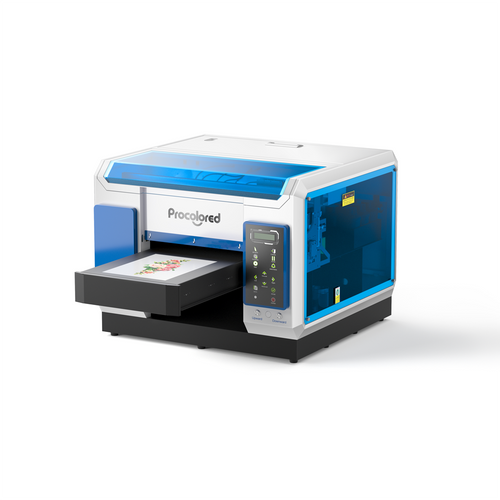

With new launch of A4 DTF printer generation 2 - L800, so far Procolored has about 6 different DTF printers on sale. How to understand each of them and opt for the most suitable one for you?

Let this shopping guide help you work out the most feasible option!

PASSAGE SUMMARY

1. Get main information from product name

Okay, yes, Procolored printers are all with super long product names. The names might trick you at the first sight but once we break them apart, you’ll be amazed about how many key information it contains.

Let’s take names of DTF printers for example (while the name rule fits all Procolored products).

The picture below shows the basic name form of Procolored product, normally it’s made up of “Procolored + model# + printer type + printable width + print head”. From a glimpse of the name, it’s easy to gain a brief understanding of what the printer is configured with.

Based on this form, we accordingly add other product characteristics to help the product be better recognized. For example, for products designed with a playful panda look on the machine cover, we add “panda” in the product name.

So far Procolored sells 6 DTF printers in total, but on the DTF collection page, it provides products of far more than 6 - coz we provide DTF printers with different bundle options to meet different needs of our customers.

Three main product bundle as below:

2. Other FAQs about Procolored DTF printers

2.1 Quick understanding about 3 main updates

For your quicker understanding, here we summarize the three main updates of Procolored DTF printers.

Ink circulation system - Siphon White Ink Circulation System is the most up-to-date patented technology of Procolored. It deploys siphon effect and diaphragm device to achieve more stable ink supply and has effectively reduced nozzle clogging issues. So far this new system has been configured to most of Procolored DTF printers to provide redefined printing experiences to our customers.

RIP software Version.2 - Based on our customer researches on RIP improvements, we have accordingly upgraded the RIP software into Version. 2 with new features such as : more optional languages (adding French, German, Italian... etc); new-set air hole setting to achieve more breathable DTF printing; visible maintenance/cleaning buttons at right corner to replace right clicking operation in V1. For more updates and instruction, check out video below:

Cutting blade - Cutting blade at the film feed position has gained broad appreciation from our customers. We’re glad to announce that all of our roller film DTF printers have been done with this upgrade and you will 100% get one with cutting blade now. For sheet film printers, please double check with our customer service first.

2.2 Sheet film or roller film?

First for your quick reference:

DTF printers with sheet film : L805, L1800, R1390

DTF printers with roller film: L800, L1800, R1390, XP600 (or DTF Pro)

For DTF printers L1800 and R1390, we offer both options: you can choose sheet film or roller film according to your own need.

But great attention here: we will gradually stop selling DTF printers with sheet film. Why? To help our customer save consumables, to be short. Sheet film greatly limits graphic dimension, especially in length. Roller film instead allows more freedom in pattern choosing and multi-patterns arrangement, effectively heightening film utilization rate.

2.3 Why there’s difference in printing speed?

First for your quick reference:

Printing speed = 8ft²/h = 0.75m²/h = L800, L805, L1800, R1390

Printing speed = 16ft²/h = 1.5m²/h = XP600 (or DTF Pro)

It’s obvious that XP600 (or DTF Pro) performs the fastest printing speed among all the Procolored DTF printers. One main reason is that it’s configured with two print heads.

Print head plays an critical role in deciding the printing speed of a printer. For DTF Pro, the two print heads (12 ink cartridges in total) are in charge of different ink type - one print head (6 ink cartridges) are for color inks listed as CCMMYK, another one (another 6 ink cartridges) are for white ink only, that would be WWWWWW. When a print head handles white ink independently, it will deposit white ink far more quickly and thus improving the whole printing pace since white ink acts as base of every printed graphic.

2.4 Should I choose a bigger printable width?

First for your quick reference:

Printable size = A4 = 8.2 inches = 210mm = L800, L805

Printable size = A3 = 13inch = 330mm = L1800, R1390, XP600 (or DTF Pro)

The selection of printable size is totally up to your personal or business need. But please note that we highly recommend L800 for DTF newbies, L1800 or R1390 for intermediate printing lovers.

Let's single out XP600 (or DTF Pro) for a dedicated discussion. XP600 (or DTF Pro) is the most expensive one among all Procolored DTF printers, for tons of good reasons of course - it’s equipped with a complete new ink circulation system, it can perform continuous printing which can hopefully achieve 50,000 square feet at a time, but it’s a more perfect choice for ...... mature printing studios that receive stably large amount orders, since it requires stable throughput to maintain its working efficiency, as well as DTF-related experiences to support its relatively complicated operations.

2.5 Which product bundle should I get?

First for your quick reference on how DTF printing works:

① Import your graphic into RIP software

② Use DTF printer to print your graphic out onto a film

③ Spread adhesive powder on the printed graphic

④ Use an oven to cure the powder

⑤ Use heat press machine to transfer graphics from film to fabrics

⑥ Peel off film

Obviously, besides a DTF printer, an extra oven and heat press are needed to complete a DTF printing process. The selection of product bundle depends on which equipment you’ve already possessed. For people who happen to start DTF printing from zero, DTF printers with ultimate or complete bundle would be the most hassle-free choice.

3. Related Equipment Selection

Let’s dive deeper into the equipment part, into question like “what’s the difference between ultimate bundle and complete bundle”. Well, good question. We’ve clarified in 1. Get Main Information from Product Name, that complete bundle refers to oven + heat press, ultimate bundle refers to powder shaker + heat press, now we go on understanding those equipment:

Oven vs powder shaker:

Oven: An oven is used to cure powder on the printed graphic and help the colors stay still. But before that, we have to manually spread powder on the graphic.

Powder shaker: This is a magic machine that frees you from tedious powder spreading. When a graphic is printed out, this machine automatically takes over the graphic, processes powder-spreading, then oven-curing, and ta-da, you can go ahead to the heat pressing part.

So should you get an oven or a powder shaker? Spreading powder is not that hard of course, but if you have to handle like 20, 30 or even hundreds of printings everyday, please consider getting yourself a powder shaker.

Heat press: Heat press normally is designed with a heating pad to provide heat and press on the cured graphic. The old version of heat press we ever provided is a traditional one, that involves manpower in pressing down or lifting up the heating pad.

Now we’ve launched a brand new one - Procolored Panda Heat Press Machine.

Designed with playful appearance of panda face, and flexible knob switch supporting easier control, this heat press remarkably features an automatically closing & opening cover - the heating cover will automatically close up to begin a task and open when the task is over, requiring less manual effort.

Check below video for further live demos. It has already been included in all DTF printer bundles!

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!