About UV Technology

UV printing, also known as ultraviolet printing, is a digital printing technology that uses ultraviolet (UV) light to cure or dry inks and coatings almost instantly as they are printed onto various substrates. This technology is commonly used in commercial printing, packaging, signage, and industrial applications.

Printing Substate and Coating

Using a UV printer is typically for printing on hard substrates such as glass, metal sheets, acrylic, and so on. With the help of some fixtures, it is also possible to print on cylindrical objects like cups or mugs. If you want to print on spherical objects or fixed-size cards, you can customize fixtures to improve printing efficiency.

Of course, if the printed patterns are prone to smudging or peeling, you can apply coatings on the surface of the substrate to enhance the adhesion of the images. Common coatings include acrylic coatings, metal coatings, and so on. After using them, the images adhere more securely and become more durable.

The Optimal Printing Distance

Procolored's UV printer features automatic height measurement. There are two infrared light emitters on both sides of the printer platform. When the platform raises the substrate to the height of the infrared beams, it automatically stops ascending. The distance from the infrared beams to the print head is the optimal printing distance, typically around 2mm.

UV ink comes in two types: hard ink and soft ink. Soft ink-printed images are less prone to bending and cracking, making them suitable for printing on materials like leather and paper. Hard ink offers stronger adhesion and is suitable for printing on materials like metal sheets and acrylic. Note that soft ink and hard ink cannot be mixed due to differences in chemical composition, which can risk clogging. UV varnish is used for printing outside of colored inks to add a glossy finish to the image and provide image protection. If you want to make crystal stickers, UV varnish is an essential consumable. Without UV varnish, the printed image may not be cohesive, making it prone to splitting when peeled off, and the image may lack gloss, reducing its appeal.

The difference between UV printer and UV DTF printer

UV printers and UV DTF printers both fall under the category of UV printing machines. Both of them require UV lamps to dry and fix the ink. The key difference is that UV DTF printers have an integrated laminator that combines the printing and laminating functions, making sticker printing more convenient. However, the drawback is that UV DTF printers cannot be used for direct printing on objects; they are limited to sticker printing. On the other hand, UV printers can be used to print on various substrates, but if you want to print stickers, you would need to use a laminator to adhere A-film and B-film together. Each of these technologies has its own characteristics and applications.

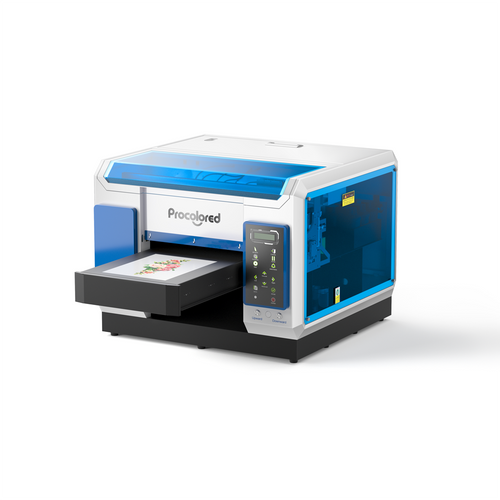

The difference between DTG printer and UV printer

DTG and UV printers are essentially similar, with the key difference being the presence of UV lamps. DTG printers print directly on fabric without the need for UV lamps to dry and cure the ink, while UV printers require UV lamps to cure the ink.

Products Compare