A Beginner's Guide: From DTG Printing to DTF

Plan to turn from traditional screen printing to emerging digital printing, but feel perplexed about all the professional digital terms? This passage will help you distinguish two main digital printings - DTG vs DTF. Keep scrolling down and get empowered!

PASSAGE SUMMARY

1.What is DTG and What is DTF

Let’s start from a brief understanding of these two printing methods:

DTG printing : DTG is also known as Direct-to-Garment printing. It’s a kind of printing technique that presents printings on fabric directly.

DTF printing : DTF is also known as Direct-to-Film printing. This printing method is suitable for fabric, too. But the printing process is a bit different, as its name denotes - it first prints on PET film, than get transferred to fabric.

2.What Do They Share in Common

As two printing methods suitable for fabric, DTG and DTF are often being compared or discussed together. So what do they share in common generally?

2.1 Both are digital printing

Both DTG and DTF printing are identified as digital printing methods and are commonly used in tshirt printing industry. They both handle digital graphics and apply inkjet printing, and both require a corresponding printer to execute printing task.

Digital printing is a concept opposite to traditional printing. Take screen printing or offset printing as traditional printing examples, these printing methods rely more on physical plates to reproduce graphics. Digital printing (especially inkjet printing) instead, applies printers to interpret digital graphics and print them out via depositing inks onto printing mediums.

2.2 Both are suitable for fabrics

Both DTG and DTF are recommended to be used on fabric including clothes, coasters, blankets and so forth materials. Via close bonding between inks and fabric, they both present vivid and complete graphic reproduction on fabric.

And in recent years, with the progressive maturity printing technology, people start experimenting on applying DTG or DTF to do wood printing, and have also achieved striking printing outcomes.

2.3 Both are heat-press needed

We’ll talk about the exhaustive printing process later on, here let’s first focus on the part they both include - heat pressing.

As previously mentioned, both DTG and DTF are suitable for fabric printing. Fabric is a porous and fibrous material composed of interwoven or knitted strands, being able to absorb inks. Yet this initial absorption might be superficial and easily washable.

Heat pressing can remarkably enhance that. Heat pressing brings heat and pressure to the printing, endowing inks with stronger viscosity and fixation, and a closer integration into fabric fibers.

3.What Are the Differences

Despite of all the similarities, there are also significant differences between DTG and DTF that lead to their appliance in different areas.

3.1 Printing process

We’ve known that both DTG and DTF require heat pressing session, but before and after that, their printing processes are quite different.

DTG printing directly prints on fabric, and the main working process works like:

①Confirm graphic : Confirm the graphic that you’re going to print.

②Pre-treat fabric : Apply pre-treatment liquid on the desired fabric. This liquid can enhance ink absorption and prevent inks from spreading.

③Heat press/iron press : Use a heat press to even the fabric.

④Proceed printing : Use a DTG printer to print the graphic out onto fabric directly.

⑤Heat press/iron press : Use a heat press to apply heat and pressure on the printed graphic.

DTF printing instead, performs indirect printing on fabric, following the procedures as below:

①Confirm graphic : Confirm the graphic that you’re going to print.

②Proceed printing : Use a DTF printer to print the graphic out onto PET film,

③Spread powder : Spread adhesive powder onto the printed graphic.

④Cure powder : Use an oven to dry the powder.

⑤Heat press : Use a heat press to transfer graphic from film to fabric.

⑥Peel off film : When the printing finally cools down, peel off film.

True that DTG printing requires less procedures. But when it comes to actual practice, less time will be needed for DTF printing when printing the same graphic.

3.2 Fabric compatibility

DTG and DTF can both be applied to fabrics, but with different fabric scope.

It’s more recommended to perform DTG printing on fabrics composed of over 80% cotton, to achieve better printing outcome.

Comparatively, DTF printing can be used on a wider range of fabrics, including cotton, polyester, cotton-polyester blends, spandex, nylon, denim, canvas and so forth.

3.3 Color reproduction

DTF printing presents vibrant colors even on black fabric - photo by Procolored user Nick M.

In most cases, DTF printing tends to present more striking and vibrant printings than DTG, especially when the base fabric is in dark colors. Such difference in color reproduction is mainly caused by:

Ink absorption of different fabrics : DTG printing is better used on cotton, a fabric type that tends to absorb more inks, directly leading to a more dull color presentataion of DTG printing. Yet at the same time, with such strong absorption, DTG printing will be much softer and more breathable.

Different ink disposal : From 3.1 Printing process, it’s notable that DTF printing must undergo an oven-curing process which is not involved in DTG. Oven-curing is a process of drying the printed inks on PET film, it helps lock in the color intensity and prevents potential fading or running during the subsequent transfer onto the fabric.

Different white ink layer : White ink layer as the printing base is critical in presenting graphic colors. DTF printing tends to have a thicker white ink base than DTG printing, alleviating negative effects from the base fabric colors.

3.4 Durability

Thanks to wider acceptable fabric range and stronger ink fixation, DTF printing tends to offer more durability than DTG, if treated with proper washing and care method.

4.Which One to Choose, DTG or DTF?

Now that we’ve listed out all these considerations for DTG vs DTF, how to effectively digest them and choose the right printing method for your business?

The truth is there is no clear superiority or inferiority between DTG and DTF printing, and the final selection depends on your unique needs.

Here are some takeaways to help you figure out your choice:

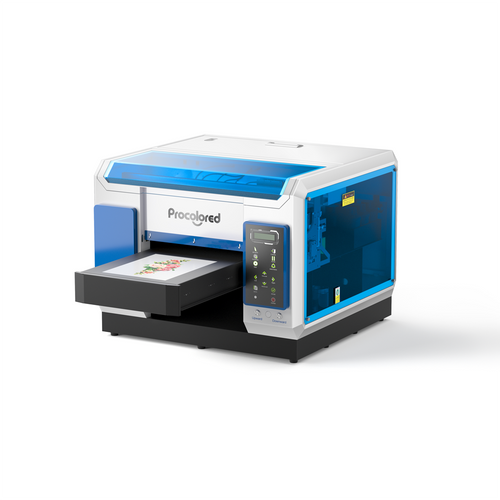

DTG printing : Suitable for users who tend to specialize in cotton fabric and be particular about fabric breathability. A desktop-sized one would be a good choice to start with!

DTF printing : Suitable for wider range of fabrics; not as breathable as DTG, but there’s improved consumable achieving breathability enhancement, please refer to What is Breathable DTF Printing for more information; durable printing outcomes and shorter printing process; more cost-efficient to start with, A4 and A3 DTF printers would be perfect for embarking on a low-invested business.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!