Product Information

Outlined |

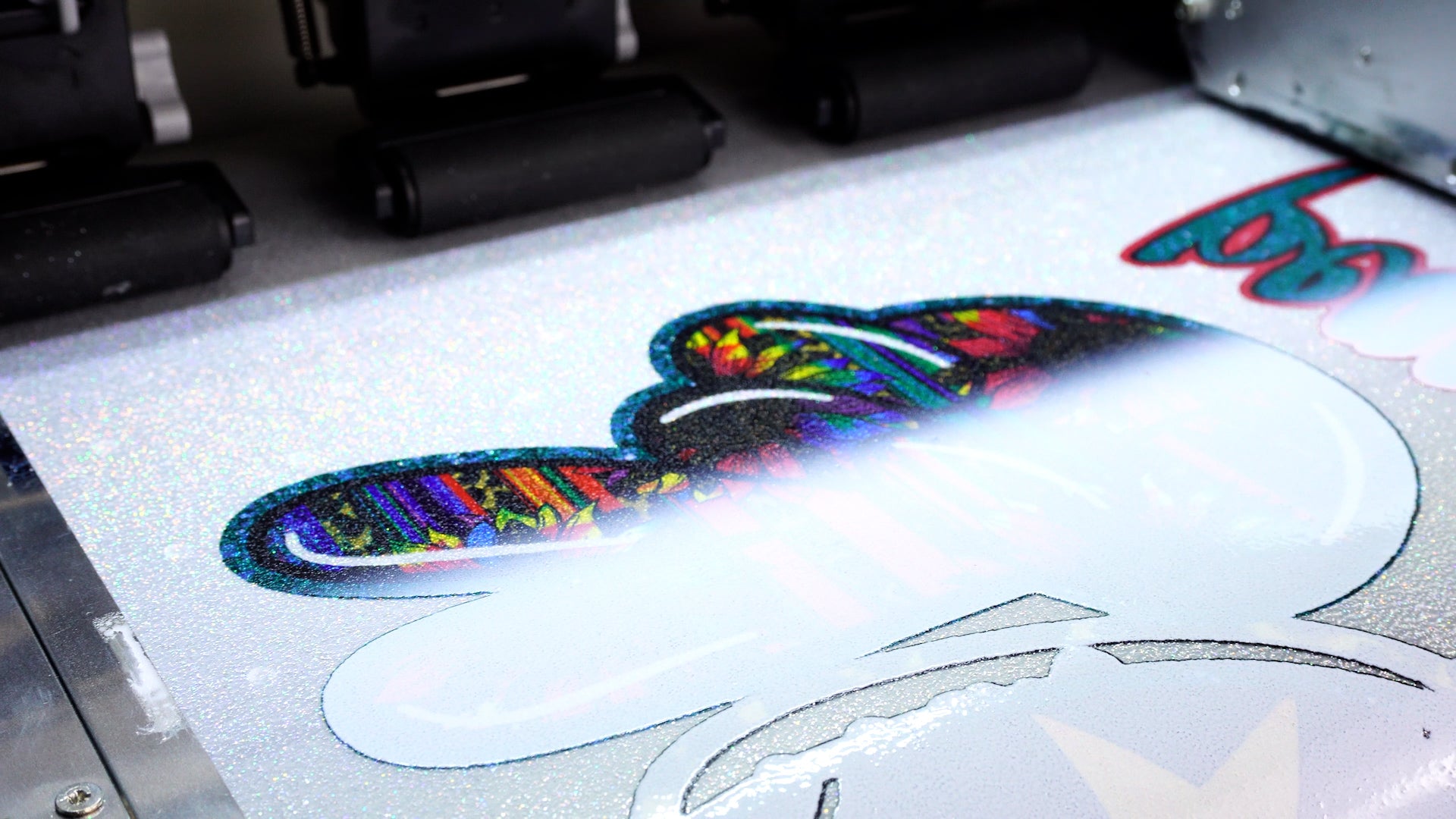

Covered with silver glittering coating, presenting a shimmering effect on the finished printings |

Description |

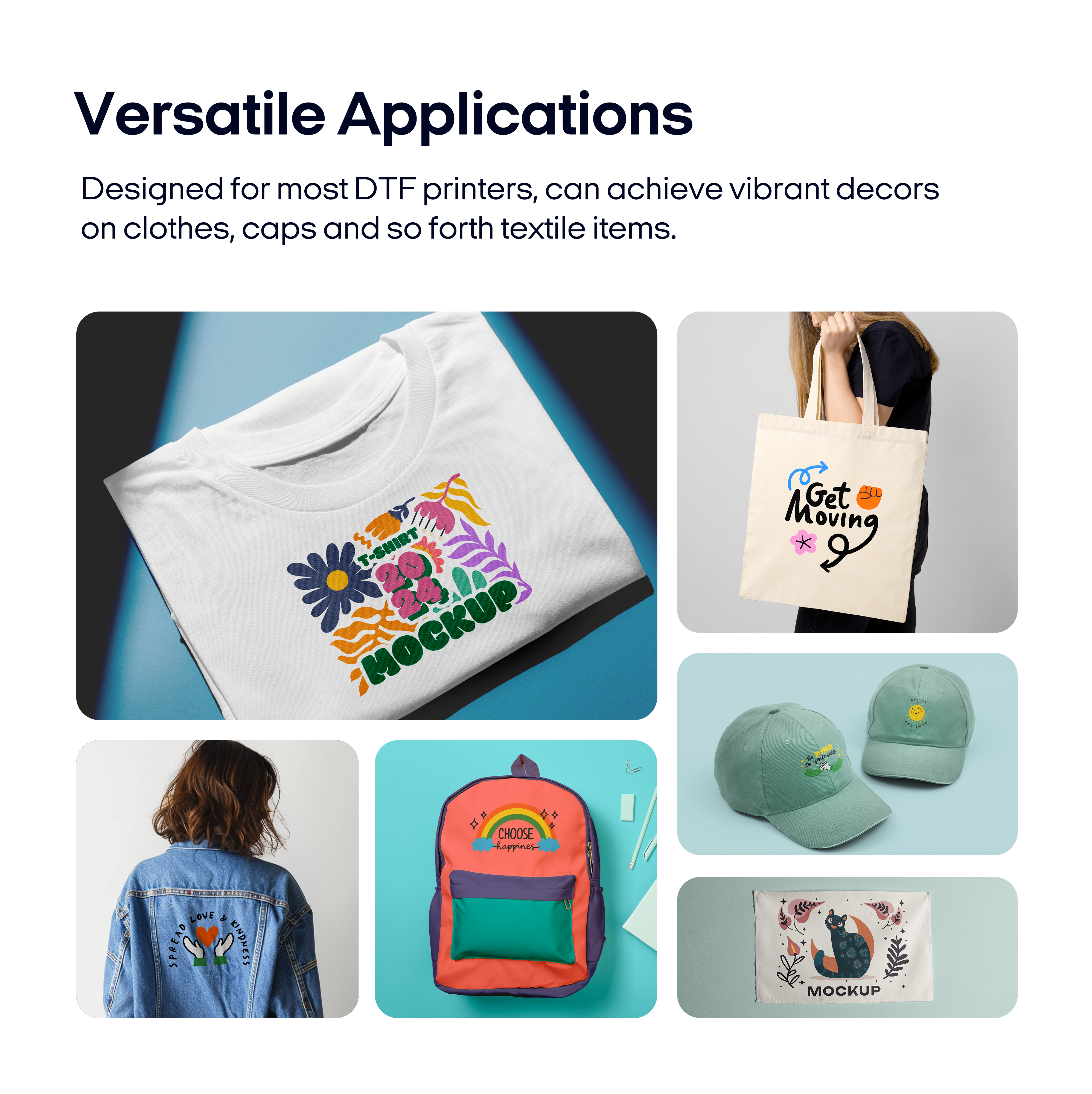

Applicable to: textile fabric, clothes, decor textile with even surface Feature: covered with silver glittering coating, presenting a shimmering effect on the finished printings; strong ink absorption, anti-powder adhesion , easy separation |

Compatibility |

Compatible printer: F13, F13 Pro |

Technical specification |

Substrate: PET with glitter coating |

Accessories |

Key feature of Glitter Film 2.0:

An upgraded density of glitter particles, which enhances reflectivity and creates a more vibrant, dazzling appearance. It can be used on A3 DTF Printers.

Glitter DTF Transfer Film Roll

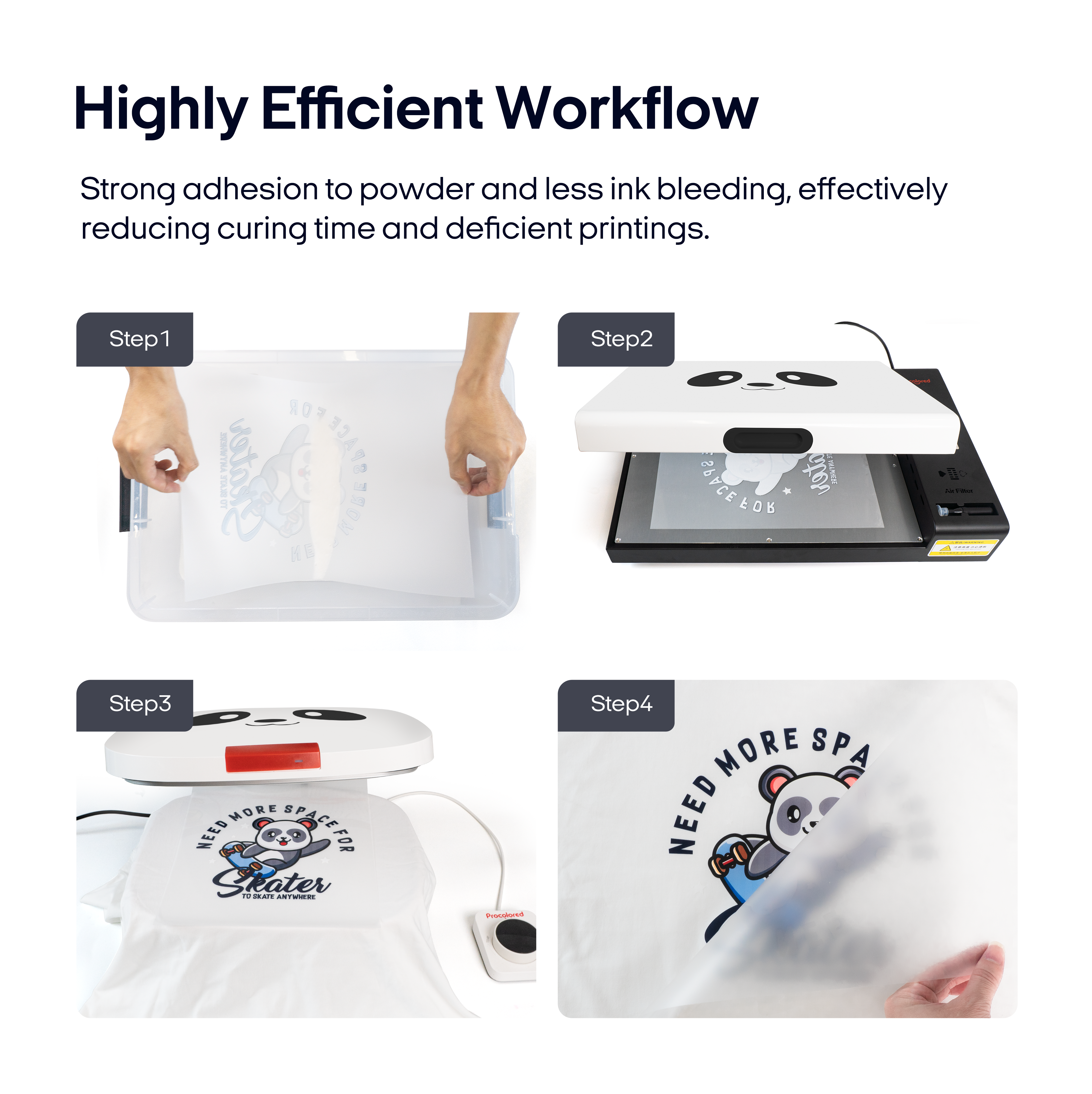

The procedure of glitter film printing and heat press.

1. Designs are printed onto the glitter film using a DTF printer, after which the print is covered adhesive powder and dried up in an oven.

2. To ensure a successful transfer, the heat press should be 160℃ and no more than 10 seconds. This prevent adhesive bonding to the film rather than the substrate.

3. Once the heat press process is complete, the film must cool down naturally before gently peeling it away.

4. Turn off the light to check out the image with a torch. The shining points on the blue back gradient background looks like the stars in the night sky.

You may also like

Combine your style with these products