Quality materials in T-shirt printing is critical because it affects the overall appearance, durability and feel of the finished T-shirt. We will discuss the impact of various materials on T-shirt printing in this article.

Print quality: High-quality fabrics transfer prints to the fabric more easily, resulting in vibrant, long-lasting prints that are less likely to fade or crack after a few washes. Poor quality materials may not fit correctly with the transfer film, resulting in poor print and even easy peeling.

Durability: Using quality materials increases the durability of your t-shirt, making it less likely to tear or wear out quickly. Durable fabrics and high-quality printing methods help ensure that designs remain intact even after repeated washings.

Comfort: High quality fabrics are softer and more comfortable to the touch than lower quality fabrics. Comfortable fabrics are a great enhancement to the customer's wearing experience.

Brand Reputation: Using high-quality materials in T-shirt printing helps to improve the overall image of the brand, customers will give positive feedback on high-quality materials and attract more people to get it.

In addition to the material of the T-shirt, T-shirt printing is also affected by the following factors

Ink quality: The ink used for printing also plays an important role in the final result. The quality of the ink affects the color vibrancy, opacity and durability of the print. Poor quality ink may not only produce poor printing results, but may also clog the print head. We recommend to go with Procolored DTF ink as it is after several calibrations and color matching.

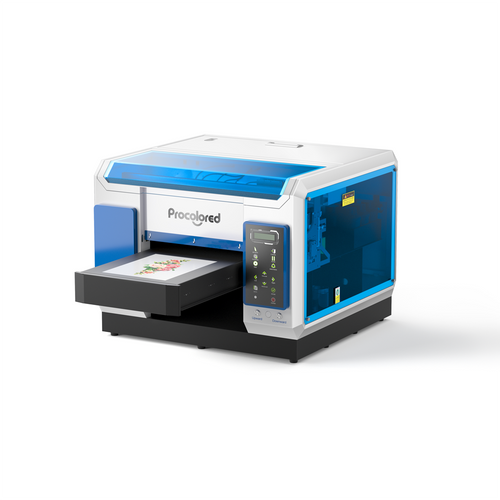

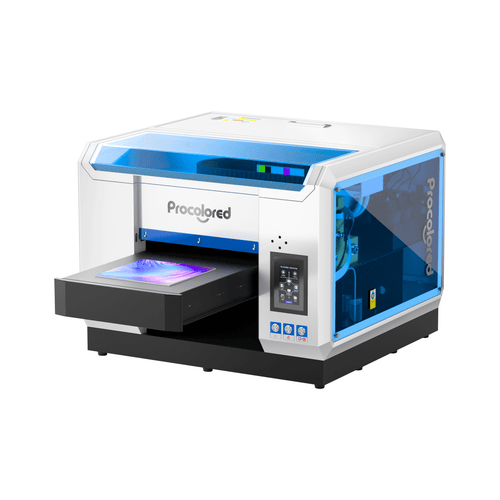

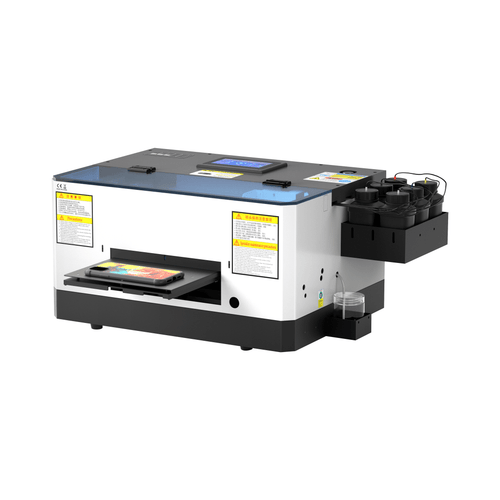

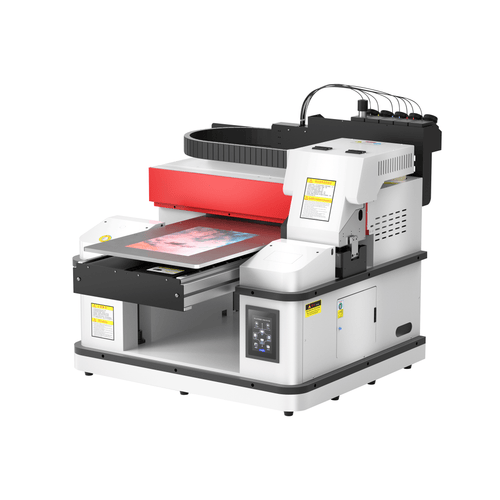

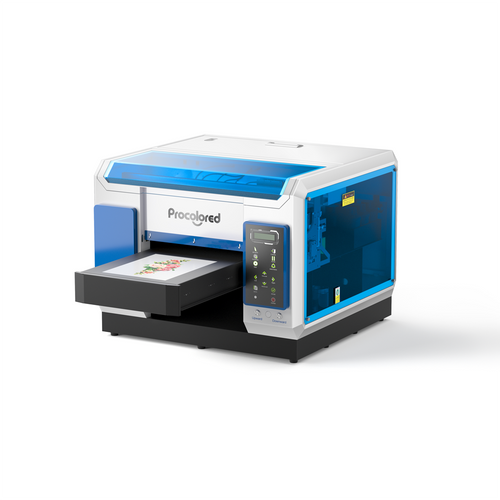

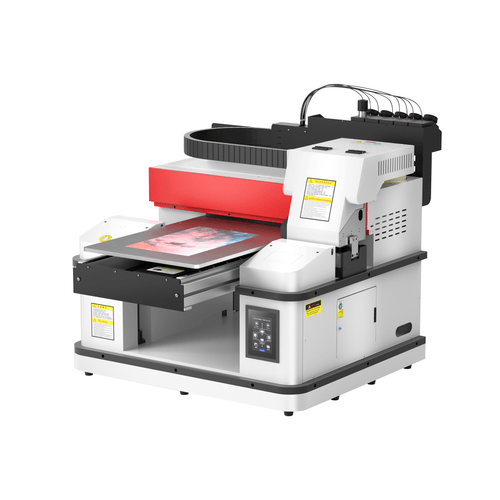

Printing techniques: Different printing techniques such as screen printing, DTG printing and DTF transfer printing can produce different results. Each process has its advantages and limitations, and the choice of process should depend on the design, fabric and quantity of the T-shirt. But the current DTF printing is changing the entire tshirt printer industry in an overwhelming trend because of its easy steps and vibrant and long-lasting colors.

Correct operation: The skills and experience of the operator also affect the quality of the T-shirt print. An experienced operator can ensure that the design is aligned correctly, for example, DTF printing generally need a mirrored images to print and the temperature of the curing oven and the heat press have to be set correctly to get a better transfer printing result.

It is important to select high quality DTF consumables as they can have a significant impact on the quality of the final printed images. A3 DTF (direct-to-film) printing is a type of printing that involves printing on a thermal transfer film and then using a heat press to transfer the design to the substrate. The quality of the DTF consumables you use, such as inks and transfer films, can affect the final print in a number of ways:

Color Accuracy: High quality DTF inks will have better color accuracy and vibrancy, which is especially important if you are printing designs with specific brand colors or trying to match the colors in your design.

Durability: The quality of the transfer film and adhesive powder will affect the durability of the final print. Quality supplies are more resistant to fading, cracking and peeling, which can extend the life of your prints.

Compatibility: Some DTF Epson I805 printers may require a specific type of consumable to work properly. Using quality supplies designed specifically for your printer can help prevent problems such as clogging, streaking or other print defects.

Overall, using high-quality DTF supplies will help ensure that your final prints are at the highest quality, accurate color, and long-lasting durability.

The choice of DTF consumables (including inks, adhesive powders and transfer films) can have a significant impact on the quality and durability of T-shirts printed using the DTF (direct-to-film) printing method.

The type of ink used affects the color vibrancy, saturation and wash resistance of the final print. It is important to choose high-quality pigment inks designed for DTF printing. These inks are known for their excellent color reproduction, adhesion to transfer films, and durability on fabrics.

Adhesive powder helps the ink adhere to the transfer film and transfer to the T-shirt during the transferring process. The type and amount of Adhesive powder used affects the quality of the print, including its adhesion to the T-shirt printer and resistance to cracking or peeling. It is important to use the correct amount of adhesive powder to ensure a smooth and consistent transfer.

The transfer film is the medium that carries the ink and adhesive powder onto the T-shirt during the printing process. The quality of the transfer film affects the clarity, definition and durability of the print. It is important to use a high quality transfer film designed specifically for DTF printing to ensure a high quality transfer.

Choosing quality DTF consumables, including inks, adhesive powders and transfer films, is critical to achieving high quality, long-lasting T-shirt prints.