Are you looking to start your own business but don't know how to get started? If so, starting your own T-shirt printing business might be the ideal pursuit. T-shirts are a popular garment, and a T-shirt printing business is highly profitable. What’s more, the equipment required to start this business is affordable.

What is DTF printing? As its name implies, it is a printing technology that is first printed on PET film, and the film is a specially designed material that can make ink form a pattern without flowing. Although it only started a few years, it has become very popular in various countries, and people marvel at its vibrant colors on the fabric. If you want to print on a t-shirt or other fabrics, it will be a good choice. Direct to Film (DTF) transfer printing, you may have heard of this technology because it was very popular at recent trade fairs and has become a popular textile printing method in many stores. Although some applications, such as sublimation and direct-to-garment, can meet this demand, DTF is a game-changing technique for the t-shirt printing business now.

This guide will cover the t-shirt printing business equipment you’ll need so you can start printing designs right away.

Ⅰ. Why Should You Consider Starting a T-shirt Business?

All this equipment can seem intimidating when you first start out, but it's worth noting that most of it will last for many years. You will get a very substantial return on your investment.

Here are the reasons why you should start your own t-shirt business:

1.Small investment, big return. On average, the consumables are relatively cheap, and the production cost of each piece of clothing or handicraft is very low, and you can get a considerable return

2.Young people are pursuing more personalization in the future, the global t-shirt printing market is huge, and the growth potential is huge for DTF practitioner.

3.Simple operation, one person can easily handle all the work, even housewives can easily complete the whole process at home

4.DTF printing colors vibrant, compared with other technologies, DTF have obvious advantages, and DTF is rapidly occupying the share of other technologies, such as sublimation and DTG.

Ⅱ. What do you need for the DTF printing?

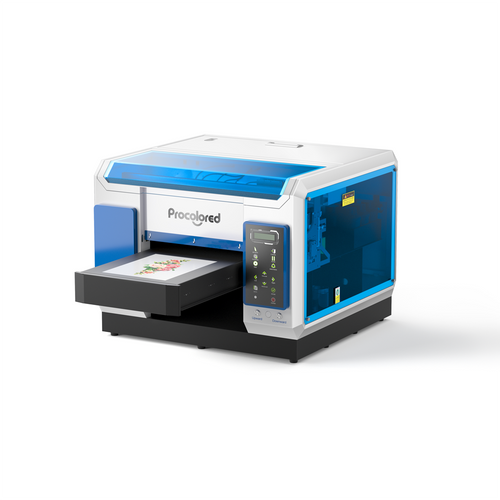

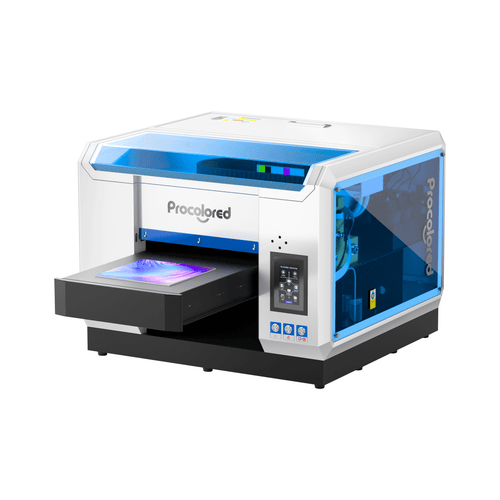

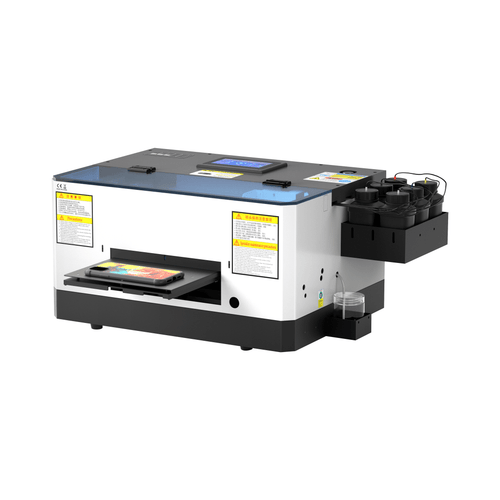

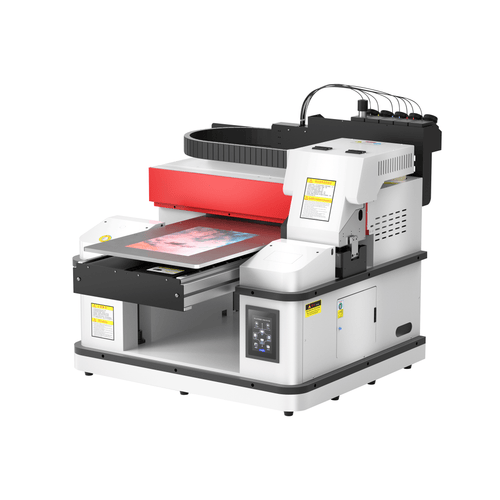

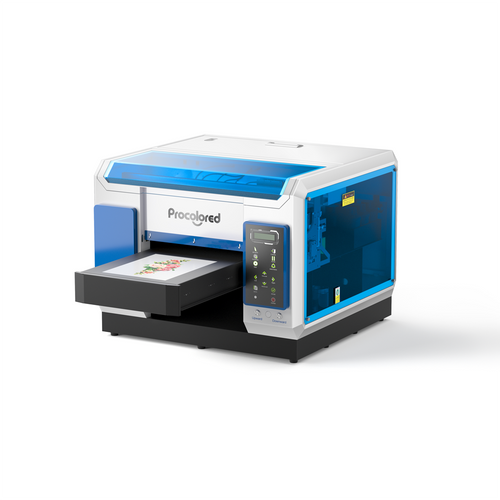

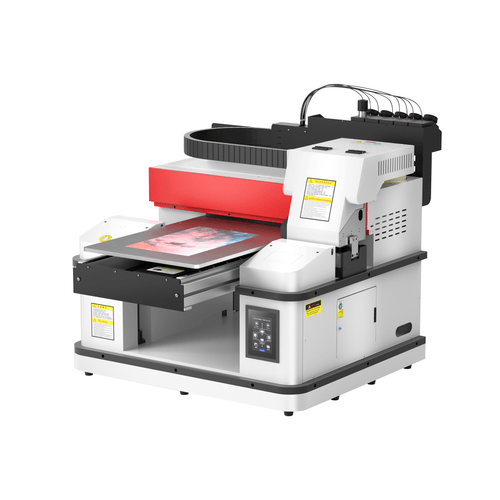

- DTF printer——A DTF tshirt printer will be one of the most important pieces of equipment you will ever buy for your t-shirt printing business. (DTF) direct to film printing is a unique printing technology that involves printing designs onto special films for transfer onto garments.

-

Curing oven or powder shake machine

- Heat press machine

- Computer with windows system

- Transfer media: T-shirtor other fabric you want to printing on

- Consumables (PET film, hot melt adhesive powder, DTF ink)

Ⅲ. How to use the printer to print?

Firstly, create your own design on the computer.

Secondly, print out the design on PET film using a DTF printer.

Thirdly, place the PET film in the oven and bake it (usually at 150 degrees for 1 minute). Fourthly, after the PET film has been baked, the PET film is placed on the T-shirt and then put together in a heat press.

Finally, the design on the film is transferred to the T-shirt by the heat press.

Ⅳ. How to make money with DTF printers?

- Selling T-shirts printed by DTF printers

①Buy some pure color t shirts, each = US$2/pc

②Printing cost is US$0.6/pc. So the printed t shirt cost= 2+0.6=2.6 USD

③Selling unit cost =US$30

④1 pc profit=30-2.6-27.4USD

Print 50 pcs each day, A month = 1500 pcs

A month profit: 27.4*1500=41,100USD

Read how to start a tshirt business

- Selling printed paints

①Printing cost is US$0.6/pc.

②Selling unit cost =US$15

③1 pc profit=15-0.6-14.4USD

Print 50 pcs each day, A month = 1500 pcs

A month profit: 14.4*1500=21,600USD

Ⅴ. Differences and advantages

Compared with other technologies, DTF is undoubtedly simpler and more convenient, and the printing image is more vibrant. DTG not only requires pretreatment, but also has restrictions on fabrics and colors. The effect of dark colors is poor, and if the fabric contains less than 80% cotton, it will also have poor effects too. Although the operation process of dye sublimation is similar to DTF, dye sublimation also has requirements for fabrics, because the transfer printing of dye sublimation needs to reach above 200 degrees Celsius, and some fabrics will be affected at such a temperature. Screen printing is already an old technology, the efficiency is very low, and it is not suitable for fast printing work. Embroidery is only suitable for logo and small pattern, and it is not easy to operate, also has many limitations

Key Word:

T-shirt printing

T-shirt business

Customized T-shirt

DTF

DTG

Dye Sublimation