Feeling getting a DTF printer means endless expenditure?

DTF printer is easy to acquire, but the real work begins afterwards - supplementary inks, run-out films, occasional issues forcing your work interrupted. Still, there are ways to somehow slow down such consumables consumption and reduce avoidable machine malfunction. Scroll down to find out how.

PASSAGE SUMMARY

In the ongoing Procolored April Event, we started a DTF printing challenge, encouraging our beloved users to seek ways of producing the most cost-efficient DTF printing all together.

To take part in this challenge, the participants should first download the given sample graphic, replicate it and arrange them as most as they can in an A3-wide film. The participant who’s work involves most patterns in the shortest film length will be the final winner.

Such practice as printing more graphics on a page in fact is one of the practical ways of saving printing expenditure. In the following passage, we will also discuss some more other ways of cost-effective DTF printing methods.

1. Print more graphics on a page

DTF graphics are not like texts, they can be integrated, combined and printed together even though they’re of different themes, sizes or shapes.

Printing more graphics on a page can help fully utilize the film space and effectively decelerate the film consumption. Yet to correctly implement this, two key points should be paid attention to:

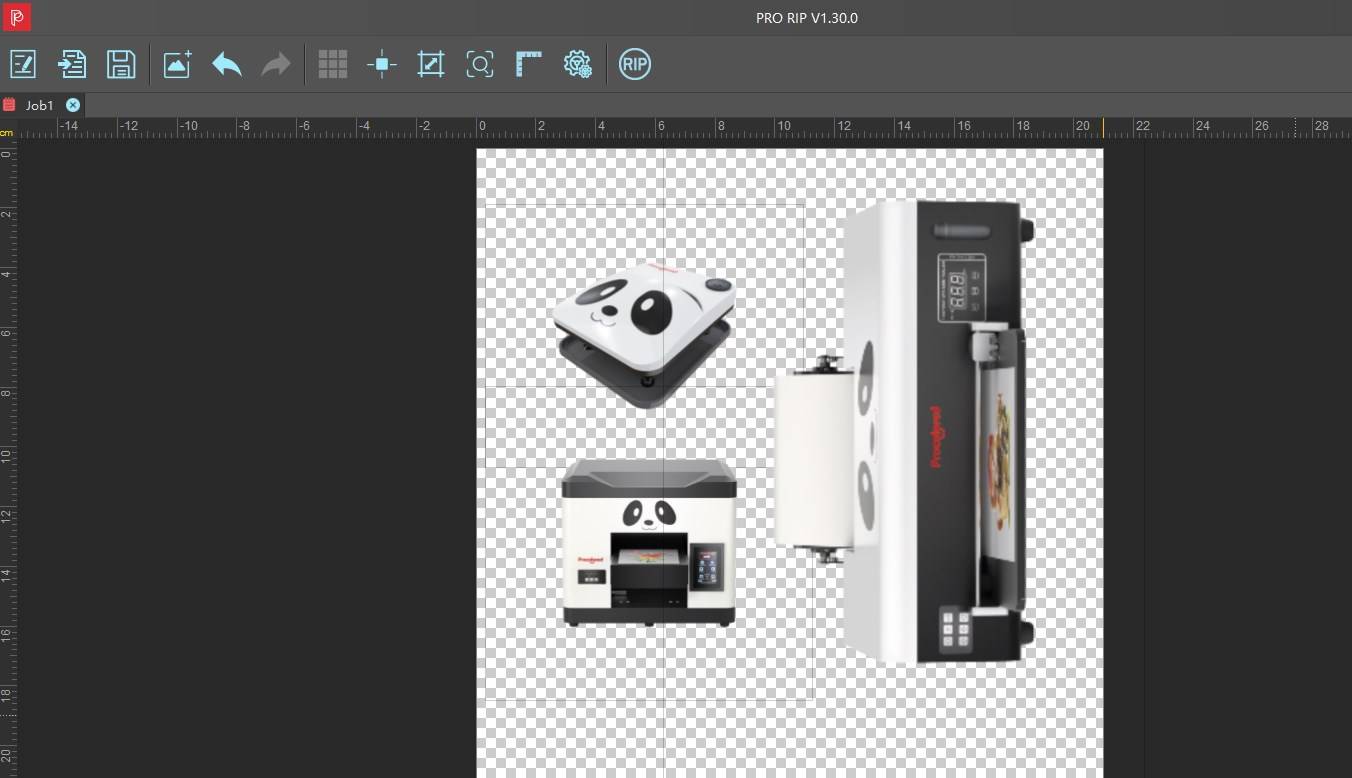

If it’s possible and practical, set your graphic background as a transparent one, this will allow you more freedom in creating your own unique printing layout since the main body of your graphics can be moved as close as possible.

When you’re dealing with small graphics, before pressing the RIP button to start printing, better zoom in the layout to make sure the main bodies of your graphics are not overlapped with each other and can be printed out completely.

2. Preview before printing

As it’s mentioned in the previous paragraph, make sure your graphics are not overlapped is one thing you should double check before printing. And things below should also be taken into consideration, too:

Printed color preview

a) Before importing your graphics into RIP software, it’s highly recommended to convert your graphics into CMYK mode first. Converting your artwork from RGB to CMYK ensures that the colors will be represented as closely as possible to how they will appear in the final printed product.

b) Before starting your printing work, always remember to get the printer test chart or even CMYK test chart first as below. Both charts can help you understand if the printer or ink is in healthy working status or not.

Printed position preview

a) Confirm twice about the graphic size by checking the X and Y values in RIP software. Don’t waste your inks and films on continuous trial printings due to graphic size errors.

b) Confirm the printed position, not just where the graphics are on the software layout, but also the margin setting of different printers.

For Procolored DTF printer DTF Pro, if your printed graphics lie way out of the film, you can adjust the margin values in PrintEXP software → settings.

For other Procolored DTF printers, please make sure your film is installed correctly and is always placed to the right of the printer, before printing. Take DTF L1800 for example, set your film to the right as the picture shows.

3. Execute the printings concurrently

As we’ve suggested in all tutorials and maintenance guides, it’s highly recommended to turn on your printer and proceed all the necessary cleanings and tests every day to better maintain its high performance. And of course, these tests will consume a rather volume of your inks.

For users that bought printers for individual use, these consumption is inevitable because they’re a recommended must of daily maintenance, even though the users may not have rather stable and considerable printing tasks awaiting to be accomplished.

But for DTF printer users who have already gained stable printing orders, it’s highly recommended to concurrently proceed the everyday printing plans in a specific period of a day, with two reasons:

As it’s clarified as above, concurrently working in a period of a day ideally only needs a one-time self-cleaning of the machine. Isn’t that cost-efficient enough? A printer cleaning at 2pm consumes your inks but guaranteeing an entire afternoon’s marvelous printing works?

Second, continuous working will highly improve the stability of white ink. That means, the ink supplying and presentation would be rather consistent and reliable, competent of providing high quality printing outputs for a long working time.

4. Choose a reliable and efficient printer brand

Printing on a budget doesn’t mean you have to bundle your printing hobby or small business with a cheap but whatever printer brand. A more reliable printer brand may cost you more at the very first beginning, but its lasting high efficiency will greatly improve your upcoming using experiences and help you save great deal money, in the ways of:

Printer performance - A high-configuration printer not only provides vibrant outputs, but also presents smooth workflows without frequent malfunction. As the printer efficiently works as your back-up, you now finally save yourself from the loss caused by printer repairing or business interruption.

Consumables compatibility - For DTF printing, the compatibility among consumables like DTF inks, films and adhesive powders significantly decide the printing quality on fabrics. A reliable printer brand is more likely to provide high quality consumables which enable intact, durable and attainable printing and patching, reducing printing deficient rate.

Customer services - A reliable brand must try its best to provide instant and convenient help for the customers in need, through official brand channels from blogs, social medias to personal services. Through fetching such handy help freely (mostly) and instantly, users will be more likely to solve their daily machine issues in a shorter time.

5. Do regular maintenance and calibration

As it’s mentioned from the start of this passage - the purchase is the easy part; it's the upkeep that's the headache. A printer without daily and regular maintenance is just like a sitting timebomb - when the nozzle finally clogs, when the ink residue finally accumulates to its volume ceiling, when the guide rail finally out of lubricating oil, time for you to pay for the “bombing”.

Just take some time reading, watching and practising all the maintenance procedures suggested by the printer brand or other seasoned users. When finally being familiar with all the steps, start to set your own maintenance routine and schedule, and take this as the most important investment to your printing business. You won’t regret it.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!